Page 101 - The Tribology Handbook

P. 101

A17 Tilting pad thrust bearings

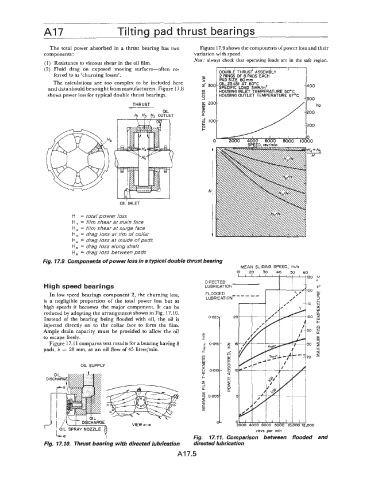

The total power absorbed in a thrust bearing has two Figure 17.9 shows the components ofpower loss and their

components : variation with speed.

Note: always check that operating loads are in the safe region.

(1) Resistance to viscous shear in the oil film.

(2) Fluid drag on exposed moving surfaces-often re-

DOUELE THRUS? ASSEMBLY

ferred to as 'churning losses'. I

2 RINGS OF 8 PADS EACH

PAD SIZE 60mm

The calculations are too complex to be included here x- 300 OIL 25CSt AT 60'C

and data should be sought from manufacturers. Figure 17.8 SPECIFIC LOAD 3MN/m2 400

HOUSING INLET TEMPERATURE 5OoC

shows power loss for typical double thrust bearings. HOUSING OUTLET TEMPERATURE 67OC

300

THRUST

OIL

yi H3 yz OUTLET

OIL INLET

H = total power loss

H = film shear at main face

H, = film shear at surge face

H, = drag loss at rim of collar

H, = drag loss at inside of pads

H, = drag loss along shaft

H, = drag loss between pads

Fig. 17.9 Components of power loss in a typical double thrust bearing

MEAN SLIDING SPEED, m/S

10 20 30 40 50 60

130 ou

FLOODED - - - - - -

High speed bearings LUBRICATION 120 t-

In low speed bearings component 2, the churning loss, LT

3

is a negligible proportion of the total power loss but at LUBRICATION 110 $

high speeds it becomes the major component. It can be LL

w

reduced by adopting the arrangement shown in Fig. 17.10. a

Instead of the bearing being flooded with oil, the oil is 100 +

injected directly on to the collar face to form the film. 0

Ample drain capacity must be provided to allow the oil 90 2

to escape freely. 5

Figure 17.1 1 compares test results for a bearing having 8 80 $

pads, b = 28 mrn, at an oil flow of 45 litreslrnin. X

U

70

OIL SUPPLY

2000 4000 6000 8000 10,000 12,000

revs per rnin

Fig. 17.11. Comparison between flooded and

Fig. 17. IO. Thrust bearing with directed lubrication directed lubrication

A17.5