Page 102 - The Tribology Handbook

P. 102

Tilting pad thrust bearings A17

Oil flow STARTING UNDER LOAD

Oil is circulated through the bearing to provide lubrica- In certain applications, notably vertical axis machines the

tion and to remove the heat resulting from the power loss. bearing must start up under load. The coefficient of

It is usual to supply oil at about 50°C and to allow for friction at break-away is about 0.15 and starting torque

a temperature rise through the bearing of about 17°C. can be calculated on the Mean Diameter.

There is some. latitude in the choice of oil flow and The specific load at start should not exceed 70% of the

temperature rise, but large deviations from these figures maximum allowable where acceleration is rapid and 50%

will affect the performance of the bearing. where starting is slow.

Where load or torque at start are higher than accept-

The required toil flow may be calculated from the power able, or for large machines where starting may be quite

loss as follows:- slow a jacking oil system can be fitted. This eliminates

friction and wear.

Power Loss (kW)

Oil flow (litredmin) = 35.8 X BEARINGS FOR VERY HIGH SPEEDS AND

Temperature Rise ("C) LOADS

Power Loss (hp)

Oil Flow (US gals/min)= 12.7 x Traditionally the thrust pads are faced with whitemetal

Temperature Rise (OF) and this is still the most commonly used material. But,

with increasingly higher specific loads and speeds the pad

surface temperature will exceed the permissible limit for

whitemetal - usually a design temperature of 130°C.

Two alternative approaches are available:-

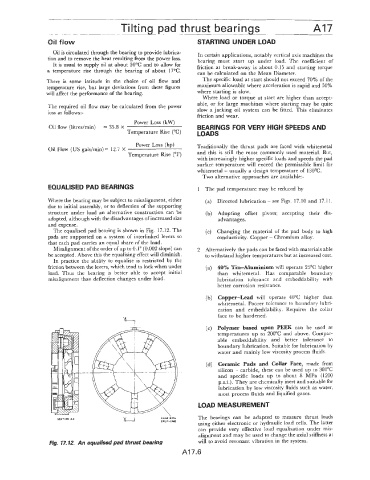

EQUALISED PAD BEARINGS 1 The pad temperature may be reduced by

Where the bearing may be subject to misalignment, either (a) Directed lubrication - see Figs. 17.10 and 17.11.

due to initial assembly, or to deflection of the supporting

structure under load an alternative construction can be (b) Adopting offset pivots; accepting their dis-

adopted, although with the disadvantages of increased size advantages.

and expense.

The equalised pad bearing is shown in Fig. 17.12. The (c) Changing the material of the pad body to high

pads are supported on a system of interlinked levers so conductivity. Copper - Chromium alloy.

that each pad carries an equal share of the load.

Misalignment of the order of up to 0.1" (0.002 slope) can 2 Alternatively the pads can be faced with materials able

be accepted. Above this the equalising effect will diminish. to withstand higher temperatures but at increased cost.

In practice the ability to equalise is restricted by the

friction between the levers, which tend to lock when under 40% Tin-Aluminium wiIl operate 25°C higher

load. Thus the bearing is better able to accept initial than whitemetal. Has comparable boundary

misalignment than deflection changes under load. lubrication tolerance and embeddability with

better corrosion resistance.

Copper-Lead will operate 40°C higher than

whitemetal. Poorer tolerance to boundary lubri-

cation and embeddability. Requires the collar

face to be hardened.

.A.

1 I

Polymer based upon PEEK can be used at

temperatures up to 200°C and above. Compar-

able embeddability and better tolerance to

boundary lubrication. Suitable for lubrication by

water and mainly low viscosity process fluids.

Ceramic Pads and Collar Face, made from

silicon - carbide, these can be used up to 380°C

and specific loads up to about 8 MPa (1200

p.s.i.). They are chemically inert and suitable for

lubrication by low viscosity fluids such as water,

most process fluids and liquified gases.

LOAD MEASUREMENT

SECTION 'AA CAGE RING The bearings can be adapted to measure thrust loads

SPLIT-LINE

using either electronic or hydraulic load cells. The latter

can provide very effective load equalisation under mis-

alignment and may be used to change the axial stiffness at

Fig. 17.12. An equalised pad thrust bearing will to avoid resonant vibration in the system.

A17.6