Page 97 - The Tribology Handbook

P. 97

A17 Tilting pad thrust bearings

The tilting pad bearing is able to accommodate a large

range of speed, load and viscosity conditions because the

pads are pivotally supported and able to assume a small

angle relative to the moving collar surface. This enables

a full hydrodynamic fluid film to be maintained between

the surfaces of pad and collar. The general proportions

and the method of operation of a typical bearing are

shown in Fig. 17.1. The pads are shown centrally pivoted,

and this type is suitable for rotation in either direction.

Each pad must receive an adequate supply of oil at its

entry edge to provide a continuous film and this is usually

achieved by immersing the bearing in a flooded chamber.

The oil is supplied at a pressure of 0.35 to 1.5 bar

(5-221bf/inz) and the outlet is restricted to control the

flow. Sealing rings are fitted at the shaft entry to maintain

the chamber full of oil. A plain journal bearing may act

also as a seal. The most commonly used arrangements

are shown in Fig. 17.2.

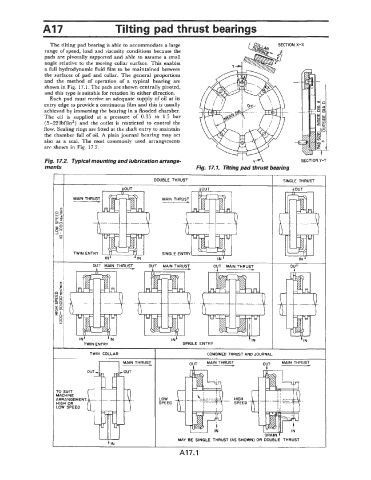

Fig. 17.2. Typical mounting and lubrication arrange- SECTION Y-Y

ments Fig. 17.1. Tilting pad thrust bearing

SINGLE THRUST

I OUT

OUT

I

TWIN COLLAR COMBINED THRUST AND JOURNAL

MAIN THRUST

TO SUIT

MACHINE

ARRANGEMENT. LOW .

HIGH OR SPEEO

LOW SPEED

MAY BE SINGLE THRUST (AS SHOWN) OR