Page 23 - Welding of Aluminium and its Alloys

P. 23

Welding metallurgy 15

Hardness

Property Tensile

strength

Ductility

Amount of cold work

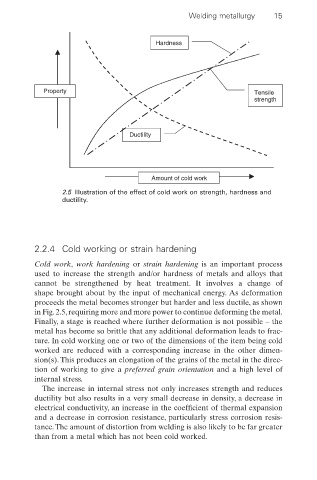

2.5 Illustration of the effect of cold work on strength, hardness and

ductility.

2.2.4 Cold working or strain hardening

Cold work, work hardening or strain hardening is an important process

used to increase the strength and/or hardness of metals and alloys that

cannot be strengthened by heat treatment. It involves a change of

shape brought about by the input of mechanical energy. As deformation

proceeds the metal becomes stronger but harder and less ductile, as shown

in Fig.2.5,requiring more and more power to continue deforming the metal.

Finally, a stage is reached where further deformation is not possible – the

metal has become so brittle that any additional deformation leads to frac-

ture. In cold working one or two of the dimensions of the item being cold

worked are reduced with a corresponding increase in the other dimen-

sion(s). This produces an elongation of the grains of the metal in the direc-

tion of working to give a preferred grain orientation and a high level of

internal stress.

The increase in internal stress not only increases strength and reduces

ductility but also results in a very small decrease in density, a decrease in

electrical conductivity, an increase in the coefficient of thermal expansion

and a decrease in corrosion resistance, particularly stress corrosion resis-

tance.The amount of distortion from welding is also likely to be far greater

than from a metal which has not been cold worked.