Page 25 - Welding of Aluminium and its Alloys

P. 25

Welding metallurgy 17

Alloy at solution treatment temperature.

Precipitates taken into solution

Rapid cool by quenching in water

Heating to

solution treatment Time at ageing temperature

followed by a

slow cool

Annealed Solution Correctly aged Overaged –

structure – treated – – fine dispersion coarse

coarse precipitates of precipitates precipitates

precipitates on retained in within the within the

the grain solution grains grains

boundaries

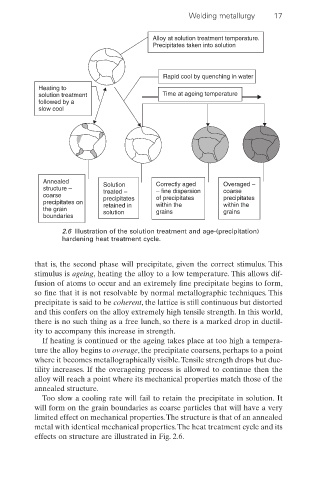

2.6 Illustration of the solution treatment and age-(precipitation)

hardening heat treatment cycle.

that is, the second phase will precipitate, given the correct stimulus. This

stimulus is ageing, heating the alloy to a low temperature. This allows dif-

fusion of atoms to occur and an extremely fine precipitate begins to form,

so fine that it is not resolvable by normal metallographic techniques. This

precipitate is said to be coherent, the lattice is still continuous but distorted

and this confers on the alloy extremely high tensile strength. In this world,

there is no such thing as a free lunch, so there is a marked drop in ductil-

ity to accompany this increase in strength.

If heating is continued or the ageing takes place at too high a tempera-

ture the alloy begins to overage, the precipitate coarsens, perhaps to a point

where it becomes metallographically visible.Tensile strength drops but duc-

tility increases. If the overageing process is allowed to continue then the

alloy will reach a point where its mechanical properties match those of the

annealed structure.

Too slow a cooling rate will fail to retain the precipitate in solution. It

will form on the grain boundaries as coarse particles that will have a very

limited effect on mechanical properties.The structure is that of an annealed

metal with identical mechanical properties.The heat treatment cycle and its

effects on structure are illustrated in Fig. 2.6.