Page 62 - Welding of Aluminium and its Alloys

P. 62

Preparation for welding 53

HF

Electrode

Cooling water

Plasma gas

Power

source

Pilot arc

Dross

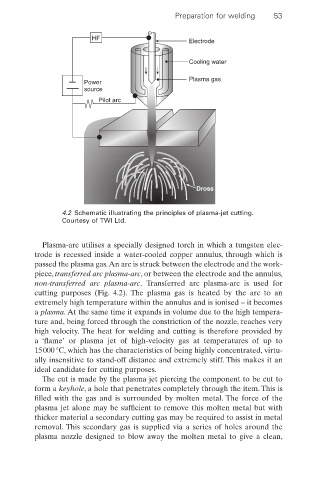

4.2 Schematic illustrating the principles of plasma-jet cutting.

Courtesy of TWI Ltd.

Plasma-arc utilises a specially designed torch in which a tungsten elec-

trode is recessed inside a water-cooled copper annulus, through which is

passed the plasma gas.An arc is struck between the electrode and the work-

piece, transferred arc plasma-arc, or between the electrode and the annulus,

non-transferred arc plasma-arc. Transferred arc plasma-arc is used for

cutting purposes (Fig. 4.2). The plasma gas is heated by the arc to an

extremely high temperature within the annulus and is ionised – it becomes

a plasma. At the same time it expands in volume due to the high tempera-

ture and, being forced through the constriction of the nozzle, reaches very

high velocity. The heat for welding and cutting is therefore provided by

a ‘flame’ or plasma jet of high-velocity gas at temperatures of up to

15000°C, which has the characteristics of being highly concentrated, virtu-

ally insensitive to stand-off distance and extremely stiff. This makes it an

ideal candidate for cutting purposes.

The cut is made by the plasma jet piercing the component to be cut to

form a keyhole, a hole that penetrates completely through the item. This is

filled with the gas and is surrounded by molten metal. The force of the

plasma jet alone may be sufficient to remove this molten metal but with

thicker material a secondary cutting gas may be required to assist in metal

removal. This secondary gas is supplied via a series of holes around the

plasma nozzle designed to blow away the molten metal to give a clean,