Page 66 - Welding of Aluminium and its Alloys

P. 66

Preparation for welding 57

Power inlet

Shielding gas inlet

Plasma gas inlet

Shielding gas

Plasma stream

Shielding gas shroud

Tungsten electrode

Path of

plasma

Direction of gouge

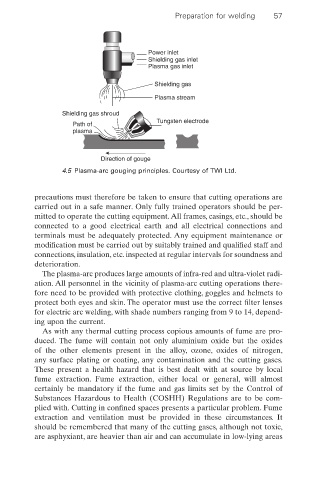

4.5 Plasma-arc gouging principles. Courtesy of TWI Ltd.

precautions must therefore be taken to ensure that cutting operations are

carried out in a safe manner. Only fully trained operators should be per-

mitted to operate the cutting equipment.All frames, casings, etc., should be

connected to a good electrical earth and all electrical connections and

terminals must be adequately protected. Any equipment maintenance or

modification must be carried out by suitably trained and qualified staff and

connections, insulation, etc. inspected at regular intervals for soundness and

deterioration.

The plasma-arc produces large amounts of infra-red and ultra-violet radi-

ation. All personnel in the vicinity of plasma-arc cutting operations there-

fore need to be provided with protective clothing, goggles and helmets to

protect both eyes and skin. The operator must use the correct filter lenses

for electric arc welding, with shade numbers ranging from 9 to 14, depend-

ing upon the current.

As with any thermal cutting process copious amounts of fume are pro-

duced. The fume will contain not only aluminium oxide but the oxides

of the other elements present in the alloy, ozone, oxides of nitrogen,

any surface plating or coating, any contamination and the cutting gases.

These present a health hazard that is best dealt with at source by local

fume extraction. Fume extraction, either local or general, will almost

certainly be mandatory if the fume and gas limits set by the Control of

Substances Hazardous to Health (COSHH) Regulations are to be com-

plied with. Cutting in confined spaces presents a particular problem. Fume

extraction and ventilation must be provided in these circumstances. It

should be remembered that many of the cutting gases, although not toxic,

are asphyxiant, are heavier than air and can accumulate in low-lying areas