Page 67 - Welding of Aluminium and its Alloys

P. 67

58 The welding of aluminium and its alloys

such as pits and wells. Forced ventilation should be considered in such

circumstances.

When plasma-arc cutting is carried out under water the dross that is

produced may build up on the tank bottom. Over a period of time this dross

reacts with the water, producing hydrogen which may accumulate under the

item being cut, leading to a risk of explosion. This is best avoided by clean-

ing the tank of the dross at regular intervals or using a forced circulation

water supply to carry away any gas as it is formed.

Plasma-arc cutting is a very noisy process, the noise level increasing as

the cutting current is increased. Ear protection is required for the operator

and personnel working in the vicinity to avoid discomfort or ear damage.

4.4 Laser beam cutting

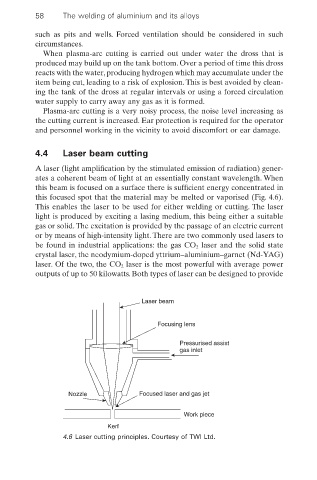

A laser (light amplification by the stimulated emission of radiation) gener-

ates a coherent beam of light at an essentially constant wavelength. When

this beam is focused on a surface there is sufficient energy concentrated in

this focused spot that the material may be melted or vaporised (Fig. 4.6).

This enables the laser to be used for either welding or cutting. The laser

light is produced by exciting a lasing medium, this being either a suitable

gas or solid.The excitation is provided by the passage of an electric current

or by means of high-intensity light. There are two commonly used lasers to

be found in industrial applications: the gas CO 2 laser and the solid state

crystal laser, the neodymium-doped yttrium–aluminium–garnet (Nd-YAG)

laser. Of the two, the CO 2 laser is the most powerful with average power

outputs of up to 50 kilowatts. Both types of laser can be designed to provide

Laser beam

Focusing lens

Pressurised assist

gas inlet

Nozzle Focused laser and gas jet

Work piece

Kerf

4.6 Laser cutting principles. Courtesy of TWI Ltd.