Page 65 - Welding of Aluminium and its Alloys

P. 65

56 The welding of aluminium and its alloys

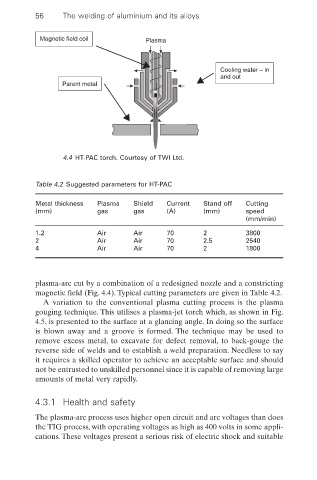

Magnetic field coil Plasma

Cooling water – in

and out

Parent metal

4.4 HT-PAC torch. Courtesy of TWI Ltd.

Table 4.2 Suggested parameters for HT-PAC

Metal thickness Plasma Shield Current Stand off Cutting

(mm) gas gas (A) (mm) speed

(mm/min)

1.2 Air Air 70 2 3800

2 Air Air 70 2.5 2540

4 Air Air 70 2 1800

plasma-arc cut by a combination of a redesigned nozzle and a constricting

magnetic field (Fig. 4.4). Typical cutting parameters are given in Table 4.2.

A variation to the conventional plasma cutting process is the plasma

gouging technique. This utilises a plasma-jet torch which, as shown in Fig.

4.5, is presented to the surface at a glancing angle. In doing so the surface

is blown away and a groove is formed. The technique may be used to

remove excess metal, to excavate for defect removal, to back-gouge the

reverse side of welds and to establish a weld preparation. Needless to say

it requires a skilled operator to achieve an acceptable surface and should

not be entrusted to unskilled personnel since it is capable of removing large

amounts of metal very rapidly.

4.3.1 Health and safety

The plasma-arc process uses higher open circuit and arc voltages than does

the TIG process, with operating voltages as high as 400 volts in some appli-

cations. These voltages present a serious risk of electric shock and suitable