Page 435 - The Mechatronics Handbook

P. 435

0066_Frame_C19 Page 57 Wednesday, January 9, 2002 5:27 PM

have no speed limitations. More generally, and especially for large machinery, dynamometers include a

specialized driving or absorbing machine. Such dynamometers are classified according to their function

as absorbing or driving (sometimes motoring). A universal dynamometer can function as either a driver

or an absorber.

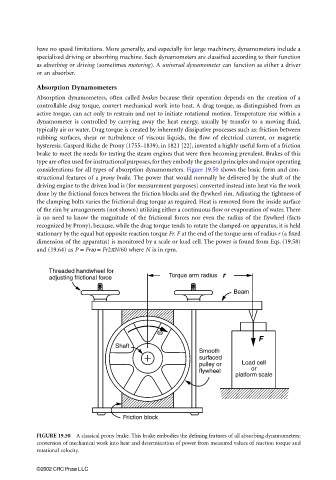

Absorption Dynamometers

Absorption dynamometers, often called brakes because their operation depends on the creation of a

controllable drag torque, convert mechanical work into heat. A drag torque, as distinguished from an

active torque, can act only to restrain and not to initiate rotational motion. Temperature rise within a

dynamometer is controlled by carrying away the heat energy, usually by transfer to a moving fluid,

typically air or water. Drag torque is created by inherently dissipative processes such as: friction between

rubbing surfaces, shear or turbulence of viscous liquids, the flow of electrical current, or magnetic

hysteresis. Gaspard Riche de Prony (1755–1839), in 1821 [22], invented a highly useful form of a friction

brake to meet the needs for testing the steam engines that were then becoming prevalent. Brakes of this

type are often used for instructional purposes, for they embody the general principles and major operating

considerations for all types of absorption dynamometers. Figure 19.50 shows the basic form and con-

structional features of a prony brake. The power that would normally be delivered by the shaft of the

driving engine to the driven load is (for measurement purposes) converted instead into heat via the work

done by the frictional forces between the friction blocks and the flywheel rim. Adjusting the tightness of

the clamping bolts varies the frictional drag torque as required. Heat is removed from the inside surface

of the rim by arrangements (not shown) utilizing either a continuous flow or evaporation of water. There

is no need to know the magnitude of the frictional forces nor even the radius of the flywheel (facts

recognized by Prony), because, while the drag torque tends to rotate the clamped-on apparatus, it is held

stationary by the equal but opposite reaction torque Fr. F at the end of the torque arm of radius r (a fixed

dimension of the apparatus) is monitored by a scale or load cell. The power is found from Eqs. (19.58)

and (19.64) as P = Frω = Fr2πN/60 where N is in rpm.

Threaded handwheel for

adjusting frictional force Torque arm radius r

Beam

ω

F

Shaft

Smooth

surfaced

pulley or Load cell

flywheel or

platform scale

Friction block

FIGURE 19.50 A classical prony brake. This brake embodies the defining features of all absorbing dynamometers:

conversion of mechanical work into heat and determination of power from measured values of reaction torque and

rotational velocity.

©2002 CRC Press LLC