Page 431 - The Mechatronics Handbook

P. 431

0066_Frame_C19 Page 53 Wednesday, January 9, 2002 5:27 PM

Toothed

Brushes To external wheels

Strain gauges circuit

Torsion

Insulator section

Slip Rings

Pickups

(a) (b)

Helical Coil

knurls or bobbin Domain wall Polarized ring

grooves

Excitation Magnetic

and sense flux line Field sensor

windings

(c) (d)

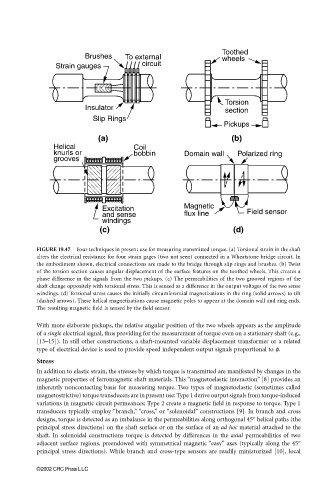

FIGURE 19.47 Four techniques in present use for measuring transmitted torque. (a) Torsional strain in the shaft

alters the electrical resistance for four strain gages (two not seen) connected in a Wheatstone bridge circuit. In

the embodiment shown, electrical connections are made to the bridge through slip rings and brushes. (b) Twist

of the torsion section causes angular displacement of the surface features on the toothed wheels. This creates a

phase difference in the signals from the two pickups. (c) The permeabilities of the two grooved regions of the

shaft change oppositely with torsional stress. This is sensed as a difference in the output voltages of the two sense

windings. (d) Torsional stress causes the initially circumferential magnetizations in the ring (solid arrows) to tilt

(dashed arrows). These helical magnetizations cause magnetic poles to appear at the domain wall and ring ends.

The resulting magnetic field is sensed by the field sensor.

With more elaborate pickups, the relative angular position of the two wheels appears as the amplitude

of a single electrical signal, thus providing for the measurement of torque even on a stationary shaft (e.g.,

[13–15]). In still other constructions, a shaft-mounted variable displacement transformer or a related

type of electrical device is used to provide speed independent output signals proportional to φ.

Stress

In addition to elastic strain, the stresses by which torque is transmitted are manifested by changes in the

magnetic properties of ferromagnetic shaft materials. This “magnetoelastic interaction” [8] provides an

inherently noncontacting basis for measuring torque. Two types of magnetoelastic (sometimes called

magnetostrictive) torque transducers are in present use: Type 1 derive output signals from torque-induced

variations in magnetic circuit permeances; Type 2 create a magnetic field in response to torque. Type 1

transducers typically employ “branch,” “cross,” or “solenoidal” constructions [9]. In branch and cross

designs, torque is detected as an imbalance in the permeabilities along orthogonal 45° helical paths (the

principal stress directions) on the shaft surface or on the surface of an ad hoc material attached to the

shaft. In solenoidal constructions torque is detected by differences in the axial permeabilities of two

adjacent surface regions, preendowed with symmetrical magnetic “easy” axes (typically along the 45°

principal stress directions). While branch and cross-type sensors are readily miniaturized [10], local

©2002 CRC Press LLC