Page 437 - The Mechatronics Handbook

P. 437

0066_Frame_C19 Page 59 Wednesday, January 9, 2002 5:27 PM

Cooling water Stator

passages windings

Trunnion

bearings Stator

G

Toothed

rotor

Input Load

coupling

S cell

Calibration Pedestal

weights

Base

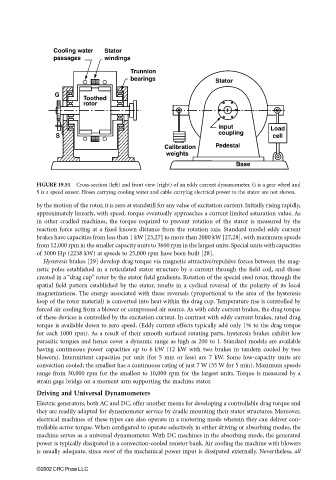

FIGURE 19.51 Cross-section (left) and front view (right) of an eddy current dynamometer. G is a gear wheel and

S is a speed sensor. Hoses carrying cooling water and cable carrying electrical power to the stator are not shown.

by the motion of the rotor, it is zero at standstill for any value of excitation current. Initially rising rapidly,

approximately linearly, with speed, torque eventually approaches a current limited saturation value. As

in other cradled machines, the torque required to prevent rotation of the stator is measured by the

reaction force acting at a fixed known distance from the rotation axis. Standard model eddy current

brakes have capacities from less than 1 kW [23,27] to more than 2000 kW [27,28], with maximum speeds

from 12,000 rpm in the smaller capacity units to 3600 rpm in the largest units. Special units with capacities

of 3000 Hp (2238 kW) at speeds to 25,000 rpm have been built [28].

Hysteresis brakes [29] develop drag torque via magnetic attractive/repulsive forces between the mag-

netic poles established in a reticulated stator structure by a current through the field coil, and those

created in a “drag cup” rotor by the stator field gradients. Rotation of the special steel rotor, through the

spatial field pattern established by the stator, results in a cyclical reversal of the polarity of its local

magnetizations. The energy associated with these reversals (proportional to the area of the hysteresis

loop of the rotor material) is converted into heat within the drag cup. Temperature rise is controlled by

forced air cooling from a blower or compressed air source. As with eddy current brakes, the drag torque

of these devices is controlled by the excitation current. In contrast with eddy current brakes, rated drag

torque is available down to zero speed. (Eddy current effects typically add only 1% to the drag torque

for each 1000 rpm). As a result of their smooth surfaced rotating parts, hysteresis brakes exhibit low

parasitic torques and hence cover a dynamic range as high as 200 to 1. Standard models are available

having continuous power capacities up to 6 kW (12 kW with two brakes in tandem cooled by two

blowers). Intermittent capacities per unit (for 5 min or less) are 7 kW. Some low-capacity units are

convection cooled; the smallest has a continuous rating of just 7 W (35 W for 5 min). Maximum speeds

range from 30,000 rpm for the smallest to 10,000 rpm for the largest units. Torque is measured by a

strain gage bridge on a moment arm supporting the machine stator.

Driving and Universal Dynamometers

Electric generators, both AC and DC, offer another means for developing a controllable drag torque and

they are readily adapted for dynamometer service by cradle mounting their stator structures. Moreover,

electrical machines of these types can also operate in a motoring mode wherein they can deliver con-

trollable active torque. When configured to operate selectively in either driving or absorbing modes, the

machine serves as a universal dynamometer. With DC machines in the absorbing mode, the generated

power is typically dissipated in a convection-cooled resistor bank. Air cooling the machine with blowers

is usually adequate, since most of the mechanical power input is dissipated externally. Nevertheless, all

©2002 CRC Press LLC