Page 73 - Theory and Design of Air Cushion Craft

P. 73

Practical formulae for predicting air cushion performance 57

Table 2.2 The principal dimensions for large and small sized MARIC skirt test rigs

Small box Big box

Box length (mm) 1050 4400

Box width (mm) 700 2230

Box height (mm) 1000 3350

Permitted max. height for test skirt (mm) 350 1500

Permitted max. width for test skirt (mm) 700 2200

4

3

Reynold's number, Re, for jet flow 2 X 10 ~4 X 10 4 5 X 10 ~ 2 X 10 5

at the air inlet of the centrifugal fan. In addition, air gap, cushion pressure and bag

pressure can all be measured. The calculation error is small because of its relatively

large size and the Re for flow in the jet can be above the minimum Re required for tur-

bulent flow.

Test data obtained are more precise and stable from the large box. The box length

is about 4 m, which was found to be the minimum length to give stable cushion pres-

sure within the box (early experiments with skirt boxes had problems with unstable

flow). This has been verified by experiments carried out.

We use the following main dimensional ratios of skirts for investigation (see Fig. 2.9):

HJH, xlB 9

where //, is the height of skirt bag, H 2 the height of fingers, S the area of the air feed-

ing hole in each finger space, B b the finger width, x the location of holes, relative to

finger attachment and 9 the angle of segment or finger outer face to the ground.

Tests for three sets of skirts were carried out in the small test rig, giving test sample

data as shown in Table 2.3. It was found that influence of H {/H 2 on static air cushion

performance of a two-dimensional skirt was small. For this reason, for simplicity, we

neglected the parameter H/H 2 to save on test time and expense on a large skirt box.

Owing to the lower accuracy both for manufacture of the skirt and regulation of hov-

ering height, as well as the irregular shape for small size of skirts, the errors for test

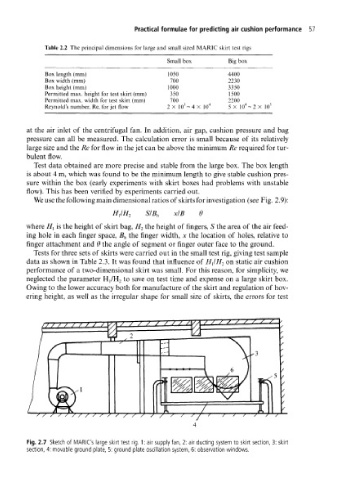

Fig. 2.7 Sketch of MARIC's large skirt test rig. 1: air supply fan, 2: air ducting system to skirt section, 3: skirt

section, 4: movable ground plate, 5: ground plate oscillation system, 6: observation windows.