Page 157 - Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

P. 157

Operational aspects of experimental liquid metal facilities 129

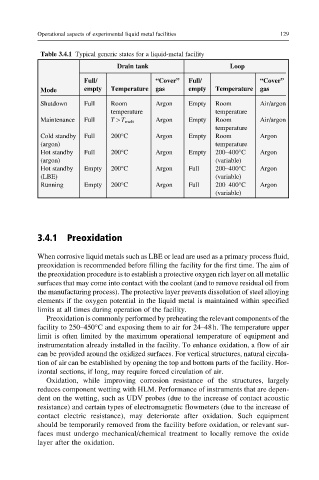

Table 3.4.1 Typical generic states for a liquid-metal facility

Drain tank Loop

Full/ “Cover” Full/ “Cover”

empty Temperature gas empty Temperature gas

Mode

Shutdown Full Room Argon Empty Room Air/argon

temperature temperature

Maintenance Full T>T melt Argon Empty Room Air/argon

temperature

Cold standby Full 200°C Argon Empty Room Argon

(argon) temperature

Hot standby Full 200°C Argon Empty 200–400°C Argon

(argon) (variable)

Hot standby Empty 200°C Argon Full 200–400°C Argon

(LBE) (variable)

Running Empty 200°C Argon Full 200–400°C Argon

(variable)

3.4.1 Preoxidation

When corrosive liquid metals such as LBE or lead are used as a primary process fluid,

preoxidation is recommended before filling the facility for the first time. The aim of

the preoxidation procedure is to establish a protective oxygen rich layer on all metallic

surfaces that may come into contact with the coolant (and to remove residual oil from

the manufacturing process). The protective layer prevents dissolution of steel alloying

elements if the oxygen potential in the liquid metal is maintained within specified

limits at all times during operation of the facility.

Preoxidation is commonly performed by preheating the relevant components of the

facility to 250–450°C and exposing them to air for 24–48h. The temperature upper

limit is often limited by the maximum operational temperature of equipment and

instrumentation already installed in the facility. To enhance oxidation, a flow of air

can be provided around the oxidized surfaces. For vertical structures, natural circula-

tion of air can be established by opening the top and bottom parts of the facility. Hor-

izontal sections, if long, may require forced circulation of air.

Oxidation, while improving corrosion resistance of the structures, largely

reduces component wetting with HLM. Performance of instruments that are depen-

dent on the wetting, such as UDV probes (due to the increase of contact acoustic

resistance) and certain types of electromagnetic flowmeters (due to the increase of

contact electric resistance), may deteriorate after oxidation. Such equipment

should be temporarily removed from the facility before oxidation, or relevant sur-

faces must undergo mechanical/chemical treatment to locally remove the oxide

layer after the oxidation.