Page 379 - Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

P. 379

342 Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

step, heat transfer in tubes, T-junctions, wake behind an obstacle, flow around a pro-

peller blade, etc. In most cases, there is an unambiguous Reynolds number and a spe-

cific turbulence model calibrated for the flow feature considered. Pool CFD models

are characterized by many features: (i) those of each component of the loop, (ii) those

of each plenum (pool) subdomain, and (iii) those of each interface, (multi-)jet flows,

restrictions, enlargements, junctions, etc. There are many associated Reynolds num-

bers, and therefore, it is not possible any more to associate a single specifically cal-

ibrated turbulence model valid for the whole CFD domain. The choice of the correct

turbulence modeling approach highly affects the accuracy of the obtained results, and

therefore, the main qualities of the applied turbulence model must be robustness and

versatility. Such models must minimize the maximum error among the different sub-

domains, in order to keep a reasonable level of accuracy under the variety of all the

encountered situations.

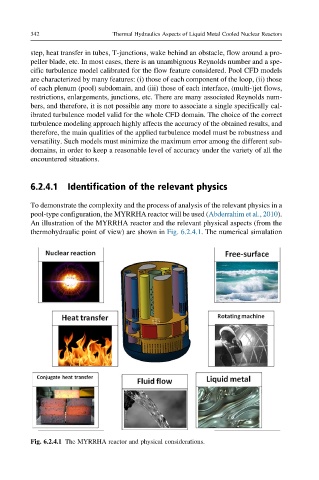

6.2.4.1 Identification of the relevant physics

To demonstrate the complexity and the process of analysis of the relevant physics in a

pool-type configuration, the MYRRHA reactor will be used (Abderrahim et al., 2010).

An illustration of the MYRRHA reactor and the relevant physical aspects (from the

thermohydraulic point of view) are shown in Fig. 6.2.4.1. The numerical simulation

Fig. 6.2.4.1 The MYRRHA reactor and physical considerations.