Page 107 - Trenchless Technology Piping Installation and Inspection

P. 107

Existing Pipeline Renewal and Replacement Methods 73

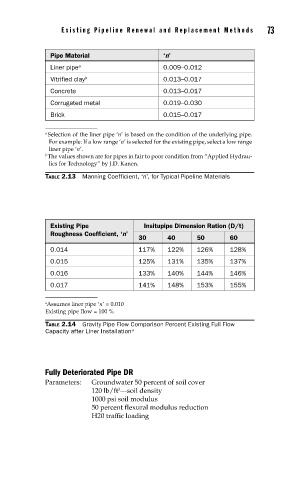

Pipe Material ‘n’

Liner pipe a 0.009–0.012

Vitrified clay b 0.013–0.017

Concrete 0.013–0.017

Corrugated metal 0.019–0.030

Brick 0.015–0.017

a Selection of the liner pipe ‘n’ is based on the condition of the underlying pipe.

For example: If a low range ‘n’ is selected for the existing pipe, select a low range

liner pipe ‘n’.

b The values shown are for pipes in fair to poor condition from “Applied Hydrau-

lics for Technology” by J.D. Kanen.

TABLE 2.13 Manning Coefficient, ‘n’, for Typical Pipeline Materials

Existing Pipe Insitupipe Dimension Ration (D/t)

Roughness Coefficient, ‘n’

30 40 50 60

0.014 117% 122% 126% 128%

0.015 125% 131% 135% 137%

0.016 133% 140% 144% 146%

0.017 141% 148% 153% 155%

a Assumes liner pipe ‘n’ = 0.010

Existing pipe flow = 100 %

TABLE 2.14 Gravity Pipe Flow Comparison Percent Existing Full Flow

Capacity after Liner Installation a

Fully Deteriorated Pipe DR

Parameters: Groundwater 50 percent of soil cover

120 lb/ft —soil density

3

1000 psi soil modulus

50 percent flexural modulus reduction

H20 traffic loading