Page 103 - Trenchless Technology Piping Installation and Inspection

P. 103

70 Cha pte r T w o

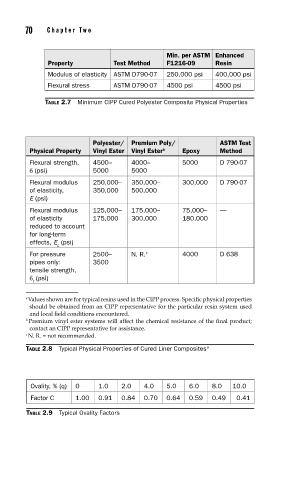

Min. per ASTM Enhanced

Property Test Method F1216-09 Resin

Modulus of elasticity ASTM D790-07 250,000 psi 400,000 psi

Flexural stress ASTM D790-07 4500 psi 4500 psi

TABLE 2.7 Minimum CIPP Cured Polyester Composite Physical Properties

Polyester/ Premium Poly/ ASTM Test

Physical Property Vinyl Ester Vinyl Ester b Epoxy Method

Flexural strength, 4500– 4000– 5000 D 790-07

(psi) 5000 5000

Flexural modulus 250,000– 350,000– 300,000 D 790-07

of elasticity, 350,000 500,000

E (psi)

Flexural modulus 125,000– 175,000– 75,000– —

of elasticity 175,000 300,000 180,000

reduced to account

for long-term

effects, E (psi)

L

For pressure 2500– N. R. c 4000 D 638

pipes only: 3500

tensile strength,

(psi)

t

a Values shown are for typical resins used in the CIPP process. Specific physical properties

should be obtained from an CIPP representative for the particular resin system used

and local field conditions encountered.

b Premium vinyl ester systems will affect the chemical resistance of the final product;

contact an CIPP representative for assistance.

c N. R. = not recommended.

TABLE 2.8 Typical Physical Properties of Cured Liner Composites a

Ovality, % (q) 0 1.0 2.0 4.0 5.0 6.0 8.0 10.0

Factor C 1.00 0.91 0.84 0.70 0.64 0.59 0.49 0.41

TABLE 2.9 Typical Ovality Factors