Page 98 - Trenchless Technology Piping Installation and Inspection

P. 98

Existing Pipeline Renewal and Replacement Methods 65

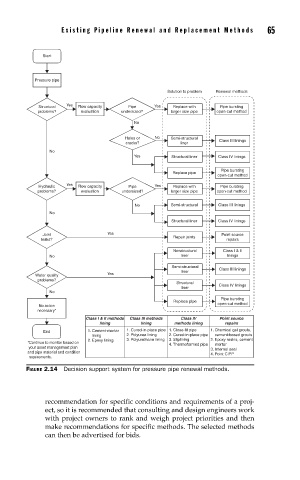

Start

Pressure pipe

Solution to problem Renewal methods

Yes

Structural Flow capacity Pipe Yes Replace with Pipe bursting

problems? evaluation undersized? larger size pipe open-cut method

No

Holes or No Semi-structural Class III linings

cracks? liner

No

Yes Structural liner Class IV linings

Pipe bursting

Replace pipe

open-cut method

Hydraulic Yes Flow capacity Pipe Yes Replace with Pipe bursting

problems? evaluation undersized? larger size pipe open-cut method

No Semi-structural Class III linings

No

Structural liner Class IV linings

Joint Yes Point source

leaks? Repair joints repairs

Nonstructural Class I & II

No liner linings

Semi-structural Class III linings

liner

Water quality Yes

problems?

Structural Class IV linings

liner

No

Pipe bursting

Replace pipe

No action open-cut method

necessary*

Class I & II methods Class III methods Class IV Point source

lining lining methods lining repairs

End 1. Cement-mortar 1. Cured-in-place pipe 1. Close-fit pipe 1. Chemical gel grouts,

lining 2. Polyurea lining 2. Cured-in-place pipe cement-based grouts

2. Epoxy lining 3. Polyurethane lining 3. Sliplining 2. Epoxy resins, cement

*Continue to monitor based on 4. Thermoformed pipe mortar

your asset management plan 3. Internal seal

and pipe material and condition 4. Point CIPP

requirements.

FIGURE 2.14 Decision support system for pressure pipe renewal methods.

recommendation for specific conditions and requirements of a proj-

ect, so it is recommended that consulting and design engineers work

with project owners to rank and weigh project priorities and then

make recommendations for specific methods. The selected methods

can then be advertised for bids.