Page 347 - Trenchless Technology Piping Installation and Inspection

P. 347

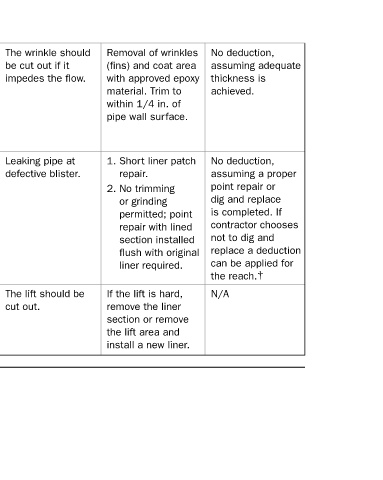

No deduction, assuming adequate thickness is achieved. No deduction, assuming a proper point repair or dig and replace is completed. If contractor chooses not to dig and replace a deduction can be applied for the reach.† N/A

Removal of wrinkles (fins) and coat area with approved epoxy material. Trim to within 1/4 in. of pipe wall surface. Short liner patch 1. repair. No trimming 2. or grinding permitted; point repair with lined section installed flush with original liner required. If the lift is hard, rem

The wrinkle should be cut out if it impedes the flow. Leaking pipe at defective blister. The lift should be cut out.

The wrinkle is acceptable if it does not disrupt or impede the normal flow characteristics of the pipeline. Repair if exceeding 5 percent of nominal diameter of existing pipe. Repair if lift in liner is exceeding 5 percent of nominal diameter of existing pipe.

Low head during inversion. Pipe undersized due to deterioration in local area. Inadequate bond between the fabric and the coating during manufacture. Premature pressure loss during installation. Insufficient cure time calculated. Addressing Potential CIPP Defects

1. 2. 1. 2.

Wrinkles (fins)— circumferential Blisters/ bubbles Lifts in liner TABLE 7.10

301