Page 129 - Tribology in Machine Design

P. 129

Friction, lubrication and wear in lower kinematic pairs 115

Thus, for an element of area d a

where R=pA is the total normal load between the bearing surfaces.

Under driving conditions, the normal load R can be maintained by a

spring force

as the friction to be overcome during engagement is then no longer

operative. Further, the spring force could be reduced to a value,

R sin a —f eR cos a, without reduction of the normal load, R, but below this

value the clutch would disengage. This conclusion assumes that

sin a >/ e cos a or tan a >/ e. Alternatively, if tan a </ e, a reversed axial force

will be necessary to disengage the clutch.

One disadvantage of this wedge action resulting from a small cone angle

is that clutches of the cone type do not readily respond to disengagement at

frequent intervals and, in consequence, are not suited to a purpose where

smooth action is desirable. On the other hand, the flat-plate clutch,

Figure 4.19

although requiring a relatively larger axial spring force, is much more

sensitive and smooth in action, and is replacing the cone clutch in modern

design.

4.6.1. Driving torque

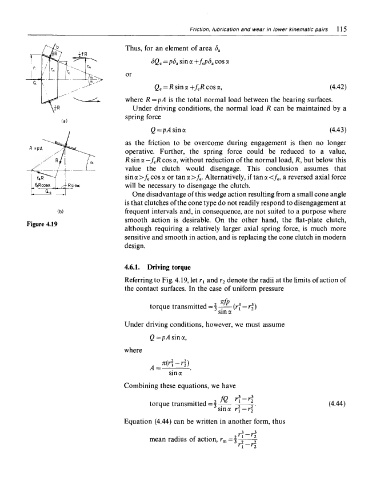

Referring to Fig. 4.19, let r t and r 2 denote the radii at the limits of action of

the contact surfaces. In the case of uniform pressure

Under driving conditions, however, we must assume

Combining these equations, we have

Equation (4.44) can be written in another form, thus