Page 291 - Tribology in Machine Design

P. 291

276 Tribology in machine design

is formed between the surfaces in contact. The friction and wear is

mainly controlled by the adsorbed surface film, a few Angstroms thick,

formed by the lubricant and its additives.

(ii) Mixed lubrication. The mixed lubrication regime is predominant when

the velocity of the gears is sufficient to develop a lubricating film but its

thickness does not provide full separation of the contacting surfaces.

As a result of that, direct contact between the highest asperities takes

place which may lead to accelerated running-in. The magnitude of the

frictional force and the rate of wear are significantly lower than in the

case of boundary lubrication.

(iii) Thick film lubrication. When the speed of the gears attains a

sufficiently high value, an elastohydrodynamic film is developed, the

thickness of which is adequate to separate completely the surfaces of

two teeth in mesh. In principle all the friction resistance comes from the

shearing of the elastohydrodynamic film. There is practically no wear if

a small amount of initial wear during running-in is ignored. The only

potential sources of wear in this lubrication regime are those due to

abrasive particles contaminating the oil and the surface fatigue

resulting in pitting. Each of the lubrication regimes can be assigned a

characteristic value of friction coefficient. In boundary lubrication,

a friction coefficient as high as 0.10-0.20 is not unusual. However,

when care is taken of the surface finish of the gear teeth and a good

boundary lubricant is used, the coefficient of friction can be substan-

tially reduced to, say, the 0.05-0.10 range. Mixed lubrication is

characterized by a coefficient of friction in the range of 0.04-0.07.

Thick film lubrication produces the lowest friction and a coefficient of

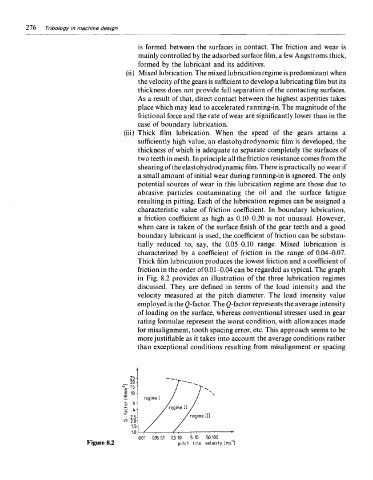

friction in the order of 0.01-0.04 can be regarded as typical. The graph

in Fig. 8.2 provides an illustration of the three lubrication regimes

discussed. They are defined in terms of the load intensity and the

velocity measured at the pitch diameter. The load intensity value

employed is the ^-factor. The Q-factor represents the average intensity

of loading on the surface, whereas conventional stresses used in gear

rating formulae represent the worst condition, with allowances made

for misalignment, tooth spacing error, etc. This approach seems to be

more justifiable as it takes into account the average conditions rather

than exceptional conditions resulting from misalignment or spacing

Figure 8.2