Page 32 - Tribology in Machine Design

P. 32

Basic principles of tribology 19

is not only a function of the usual variables, such as load, contact area

diameter and sliding velocity, but also of the angular velocity. Furthermore,

there is an additional force orthogonal to the direction of linear motion. In

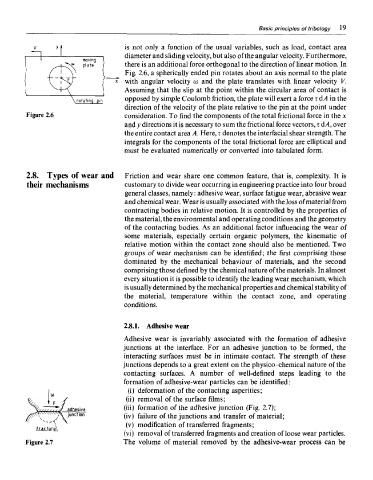

Fig. 2.6, a spherically ended pin rotates about an axis normal to the plate

with angular velocity co and the plate translates with linear velocity V.

Assuming that the slip at the point within the circular area of contact is

opposed by simple Coulomb friction, the plate will exert a force T dA in the

direction of the velocity of the plate relative to the pin at the point under

Figure 2.6 consideration. To find the components of the total frictional force in the x

and y directions it is necessary to sum the frictional force vectors, x dA, over

the entire contact area A. Here, i denotes the interfacial shear strength. The

integrals for the components of the total frictional force are elliptical and

must be evaluated numerically or converted into tabulated form.

2.8. Types of wear and Friction and wear share one common feature, that is, complexity. It is

their mechanisms customary to divide wear occurring in engineering practice into four broad

general classes, namely: adhesive wear, surface fatigue wear, abrasive wear

and chemical wear. Wear is usually associated with the loss of material from

contracting bodies in relative motion. It is controlled by the properties of

the material, the environmental and operating conditions and the geometry

of the contacting bodies. As an additional factor influencing the wear of

some materials, especially certain organic polymers, the kinematic of

relative motion within the contact zone should also be mentioned. Two

groups of wear mechanism can be identified; the first comprising those

dominated by the mechanical behaviour of materials, and the second

comprising those defined by the chemical nature of the materials. In almost

every situation it is possible to identify the leading wear mechanism, which

is usually determined by the mechanical properties and chemical stability of

the material, temperature within the contact zone, and operating

conditions.

2.8.1. Adhesive wear

Adhesive wear is invariably associated with the formation of adhesive

junctions at the interface. For an adhesive junction to be formed, the

interacting surfaces must be in intimate contact. The strength of these

junctions depends to a great extent on the physico-chemical nature of the

contacting surfaces. A number of well-defined steps leading to the

formation of adhesive-wear particles can be identified:

(i) deformation of the contacting asperities;

(ii) removal of the surface films;

(iii) formation of the adhesive junction (Fig. 2.7);

(iv) failure of the junctions and transfer of material;

(v) modification of transferred fragments;

(vi) removal of transferred fragments and creation of loose wear particles.

Figure 2.7 The volume of material removed by the adhesive-wear process can be