Page 35 - Tribology in Machine Design

P. 35

22 Tribology in machine design

models of fatigue wear usually include the concept of fatigue failure and also

of simple plastic deformation failure, which could be regarded as low-cycle

fatigue or fatigue in one loading cycle. Theories for the fatigue-life

prediction of rolling metallic contacts are of long standing. In their classical

form, they attribute fatigue failure to subsurface imperfections in the

material and they predict life as a function of the Hertz stress field,

disregarding traction. In order to interpret the effects of metal variables in

contact and to include surface topography and appreciable sliding effects,

the classical rolling contact fatigue models have been expanded and

modified. For sliding contacts, the amount of material removed due to

fatigue can be estimated from the expression

where 77 is the distribution of asperity heights, y is the particle size constant,

Si is the strain to failure in one loading cycle and H is the hardness.

It should be mentioned that, taking into account the plastic-elastic stress

fields in the subsurface regions of the sliding asperity contacts and the

possibility of dislocation interactions, wear by delamination could be

envisaged.

2.8.4. Wear due to chemical reactions

It is now accepted that the friction process itself can initiate a chemical

reaction within the contact zone. Unlike surface fatigue and abrasion,

which are mainly controlled by stress interactions and deformation

properties, wear resulting from chemical reactions induced by friction is

influenced mainly by the environment and its active interaction with the

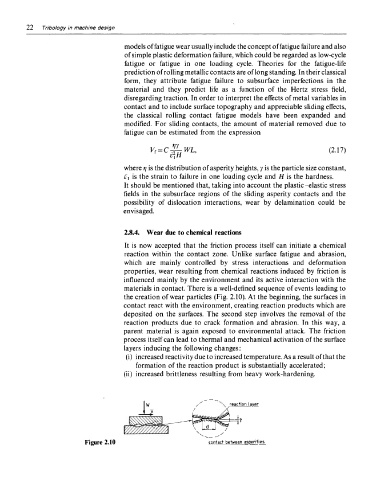

materials in contact. There is a well-defined sequence of events leading to

the creation of wear particles (Fig. 2.10). At the beginning, the surfaces in

contact react with the environment, creating reaction products which are

deposited on the surfaces. The second step involves the removal of the

reaction products due to crack formation and abrasion. In this way, a

parent material is again exposed to environmental attack. The friction

process itself can lead to thermal and mechanical activation of the surface

layers inducing the following changes:

(i) increased reactivity due to increased temperature. As a result of that the

formation of the reaction product is substantially accelerated;

(ii) increased brittleness resulting from heavy work-hardening.

Figure 2.10 contact between asperities