Page 72 - Troubleshooting Analog Circuits

P. 72

Make Good Connections 59

I

-

PROORAMYABLE

POWER

SUPPLY

2

OSCILLOSCOPE

NOTE. IC, rLMW7 OR SIMILAR OP AMP WITH t15V SUPPLIES J

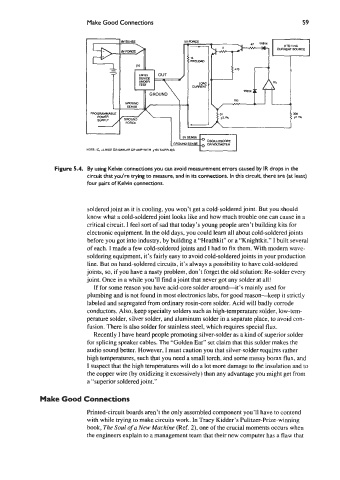

Figure 5.4. By using Kelvin connections you can avoid measurement errors caused by IR drops in the

circuit that you’re trying to measure, and in its connections. In this circuit, there are (at least)

four pairs of Kelvin connections.

soldered joint as it is cooling, you won’t get a cold-soldered joint. But you should

know what a cold-soldered joint looks like and how much trouble one can cause in a

critical circuit. I feel sort of sad that today’s young people aren’t building kits for

electronic equipment. In the old days, you could learn all about cold-soldered joints

before you got into industry, by building a “Heathkit” or a “Knightkit.” I built several

of each. I made a few cold-soldered joints and I had to fix them. With modem wave-

soldering equipment, it’s fairly easy to avoid cold-soldered joints in your production

line. But on hand-soldered circuits, it’s always a possibility to have cold-soldered

joints, so, if you have a nasty problem, don’t forget the old solution: Re-solder every

joint. Once in a while you’ll find a joint that never got any solder at all!

If for some reason you have acid-core solder around-it’s mainly used for

plumbing and is not found in most electronics labs, for good reason-keep it strictly

labeled and segregated from ordinary rosin-core solder. Acid will badly corrode

conductors. Also, keep specialty solders such as high-temperature solder, low-tem-

perature solder, silver solder, and aluminum solder in a separate place, to avoid con-

fusion. There is also solder for stainless steel, which requires special flux.

Recently I have heard people promoting silver-solder as a kind of superior solder

for splicing speaker cables. The “Golden Ear” set claim that this solder makes the

audio sound better. However, I must caution you that silver-solder requires rather

high temperatures, such that you need a small torch, and some messy borax flux, and

I suspect that the high temperatures will do a lot more damage to the insulation and to

the copper wire (by oxidizing it excessively) than any advantage you might get from

a “superior soldered joint.”

Make Good Connections

Printed-circuit boards aren’t the only assembled component you’ll have to contend

with while trying to make circuits work. In Tracy Kidder’s Pulitzer-Prize-winning

book, The Soul ofa New Machine (Ref. 2). one of the crucial moments occurs when

the engineers explain to a management team that their new computer has a flaw that