Page 237 - Understanding Automotive Electronics

P. 237

2735 | CH 7 Page 224 Tuesday, March 10, 1998 1:15 PM

7 DIGITAL ENGINE CONTROL SYSTEM

DIGITAL ENGINE CONTROL FEATURES

Recall from Chapter 5 that the primary purpose of the electronic engine

control system is to regulate the mixture (i.e., air–fuel), the ignition timing, and

EGR. Virtually all major manufacturers of cars sold in the United States (both

foreign and domestic) use the three-way catalyst for meeting exhaust emission

constraints. For such cars, the air/fuel ratio is held as closely as possible to the

stoichiometric value of about 14.7 for as much of the time as possible. Ignition

timing and EGR are controlled separately to optimize performance and fuel

economy.

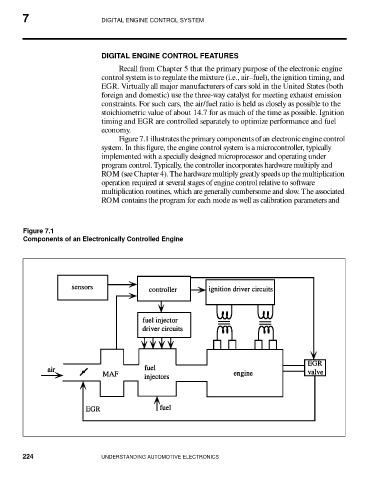

Figure 7.1 illustrates the primary components of an electronic engine control

system. In this figure, the engine control system is a microcontroller, typically

implemented with a specially designed microprocessor and operating under

program control. Typically, the controller incorporates hardware multiply and

ROM (see Chapter 4). The hardware multiply greatly speeds up the multiplication

operation required at several stages of engine control relative to software

multiplication routines, which are generally cumbersome and slow. The associated

ROM contains the program for each mode as well as calibration parameters and

Figure 7.1

Components of an Electronically Controlled Engine

224 UNDERSTANDING AUTOMOTIVE ELECTRONICS