Page 200 - Urban Construction Project Management

P. 200

Logistics 155

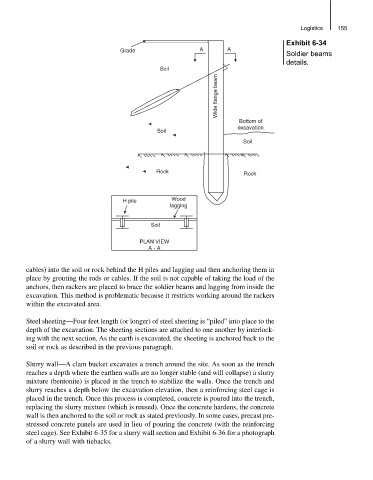

Exhibit 6-34

Grade A A

Soldier beams

details.

Soil

Wide flange beam

Bottom of

excavation

Soil

Soil

Rock

Rock

H pile Wood

lagging

Soil

PLAN VIEW

A - A

cables) into the soil or rock behind the H piles and lagging and then anchoring them in

place by grouting the rods or cables. If the soil is not capable of taking the load of the

anchors, then rackers are placed to brace the soldier beams and lagging from inside the

excavation. This method is problematic because it restricts working around the rackers

within the excavated area.

Steel sheeting—Four feet length (or longer) of steel sheeting is “piled” into place to the

depth of the excavation. The sheeting sections are attached to one another by interlock-

ing with the next section. As the earth is excavated, the sheeting is anchored back to the

soil or rock as described in the previous paragraph.

Slurry wall—A clam bucket excavates a trench around the site. As soon as the trench

reaches a depth where the earthen walls are no longer stable (and will collapse) a slurry

mixture (bentonite) is placed in the trench to stabilize the walls. Once the trench and

slurry reaches a depth below the excavation elevation, then a reinforcing steel cage is

placed in the trench. Once this process is completed, concrete is poured into the trench,

replacing the slurry mixture (which is reused). Once the concrete hardens, the concrete

wall is then anchored to the soil or rock as stated previously. In some cases, precast pre-

stressed concrete panels are used in lieu of pouring the concrete (with the reinforcing

steel cage). See Exhibit 6-35 for a slurry wall section and Exhibit 6-36 for a photograph

of a slurry wall with tiebacks.