Page 55 - Urban Construction Project Management

P. 55

30 Chapter Two

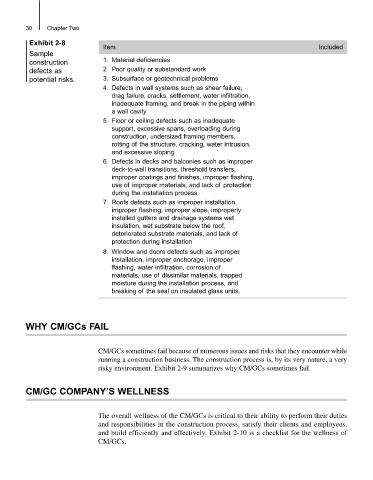

Exhibit 2-8

Item Included

Sample

construction 1. Material deficiencies

defects as 2. Poor quality or substandard work

potential risks. 3. Subsurface or geotechnical problems

4. Defects in wall systems such as shear failure,

drag failure, cracks, settlement, water infiltration,

inadequate framing, and break in the piping within

a wall cavity

5. Floor or ceiling defects such as inadequate

support, excessive spans, overloading during

construction, undersized framing members,

rotting of the structure, cracking, water intrusion,

and excessive sloping

6. Defects in decks and balconies such as improper

deck-to-wall transitions, threshold transfers,

improper coatings and finishes, improper flashing,

use of improper materials, and lack of protection

during the installation process

7. Roofs defects such as improper installation,

improper flashing, improper slope, improperly

installed gutters and drainage systems wet

insulation, wet substrate below the roof,

deteriorated substrate materials, and lack of

protection during installation

8. Window and doors defects such as improper

installation, improper anchorage, improper

flashing, water infiltration, corrosion of

materials, use of dissimilar materials, trapped

moisture during the installation process, and

breaking of the seal on insulated glass units.

WHY CM/GCs FAIL

CM/GCs sometimes fail because of numerous issues and risks that they encounter while

running a construction business. The construction process is, by its very nature, a very

risky environment. Exhibit 2-9 summarizes why CM/GCs sometimes fail.

CM/GC COMPANY’S WELLNESS

The overall wellness of the CM/GCs is critical to their ability to perform their duties

and responsibilities in the construction process, satisfy their clients and employees,

and build efficiently and effectively. Exhibit 2-10 is a checklist for the wellness of

CM/GCs.