Page 97 - Urban Construction Project Management

P. 97

Testing and Quality Control 57

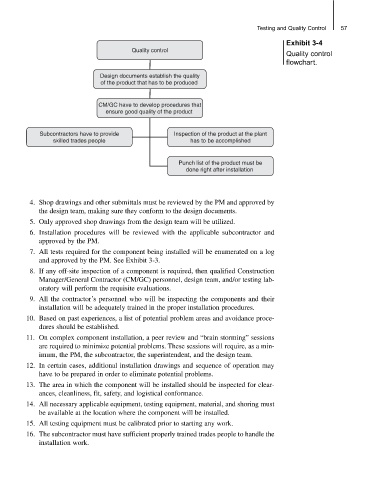

Exhibit 3-4

Quality control

Quality control

flowchart.

Design documents establish the quality

of the product that has to be produced

CM/GC have to develop procedures that

ensure good quality of the product

Subcontractors have to provide Inspection of the product at the plant

skilled trades people has to be accomplished

Punch list of the product must be

done right after installation

4. Shop drawings and other submittals must be reviewed by the PM and approved by

the design team, making sure they conform to the design documents.

5. Only approved shop drawings from the design team will be utilized.

6. Installation procedures will be reviewed with the applicable subcontractor and

approved by the PM.

7. All tests required for the component being installed will be enumerated on a log

and approved by the PM. See Exhibit 3-3.

8. If any off-site inspection of a component is required, then qualified Construction

Manager/General Contractor (CM/GC) personnel, design team, and/or testing lab-

oratory will perform the requisite evaluations.

9. All the contractor’s personnel who will be inspecting the components and their

installation will be adequately trained in the proper installation procedures.

10. Based on past experiences, a list of potential problem areas and avoidance proce-

dures should be established.

11. On complex component installation, a peer review and “brain storming” sessions

are required to minimize potential problems. These sessions will require, as a min-

imum, the PM, the subcontractor, the superintendent, and the design team.

12. In certain cases, additional installation drawings and sequence of operation may

have to be prepared in order to eliminate potential problems.

13. The area in which the component will be installed should be inspected for clear-

ances, cleanliness, fit, safety, and logistical conformance.

14. All necessary applicable equipment, testing equipment, material, and shoring must

be available at the location where the component will be installed.

15. All testing equipment must be calibrated prior to starting any work.

16. The subcontractor must have sufficient properly trained trades people to handle the

installation work.