Page 87 - Valve Selection Handbook

P. 87

74 Valve Selection Handbook

valve owes its ability to handle these fluids to the knife-edged disc, which

is capable of cutting through fibrous material, and the virtual absence of a

valve body cavity. The disc travels in lateral guides and is forced against

the seat by lugs at the bottom. If a high degree of fluid tightness is

required, the valve may also be provided with an O-ring seat seal.

Conduit Gate Valves

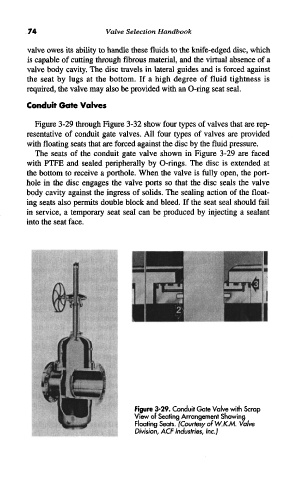

Figure 3-29 through Figure 3-32 show four types of valves that are rep-

resentative of conduit gate valves. All four types of valves are provided

with floating seats that are forced against the disc by the fluid pressure.

The seats of the conduit gate valve shown in Figure 3-29 are faced

with PTFE and sealed peripherally by O-rings. The disc is extended at

the bottom to receive a porthole. When the valve is fully open, the port-

hole in the disc engages the valve ports so that the disc seals the valve

body cavity against the ingress of solids. The sealing action of the float-

ing seats also permits double block and bleed. If the seat seal should fail

in service, a temporary seat seal can be produced by injecting a sealant

into the seat face.

Figure 3-29. Conduit Gate Valve with Scrap

View of Seating Arrangement Showing

Floating Seats. (Courtesy of W.K.M. Valve

Division, ACF Industries, Inc.)