Page 90 - Visions of the Future Chemistry and Life Science

P. 90

Diamond thin films 79

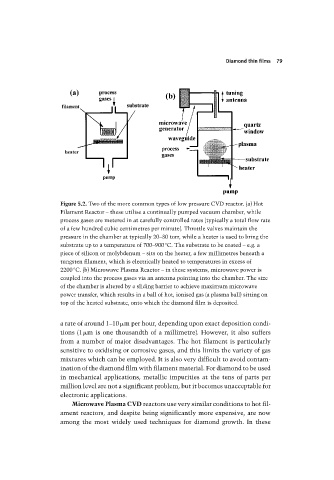

Figure 5.2. Two of the more common types of low pressure CVD reactor. (a) Hot

Filament Reactor – these utilise a continually pumped vacuum chamber, while

process gases are metered in at carefully controlled rates (typically a total flow rate

of a few hundred cubic centimetres per minute). Throttle valves maintain the

pressure in the chamber at typically 20–30 torr, while a heater is used to bring the

substrate up to a temperature of 700–900°C. The substrate to be coated – e.g. a

piece of silicon or molybdenum – sits on the heater, a few millimetres beneath a

tungsten filament, which is electrically heated to temperatures in excess of

2200°C. (b) Microwave Plasma Reactor – in these systems, microwave power is

coupled into the process gases via an antenna pointing into the chamber. The size

of the chamber is altered by a sliding barrier to achieve maximum microwave

power transfer, which results in a ball of hot, ionised gas (a plasma ball) sitting on

top of the heated substrate, onto which the diamond film is deposited.

a rate of around 1–10 m per hour, depending upon exact deposition condi-

tions (1 m is one thousandth of a millimetre). However, it also suffers

from a number of major disadvantages. The hot filament is particularly

sensitive to oxidising or corrosive gases, and this limits the variety of gas

mixtures which can be employed. It is also very difficult to avoid contam-

ination of the diamond film with filament material. For diamond to be used

in mechanical applications, metallic impurities at the tens of parts per

million level are not a significant problem, but it becomes unacceptable for

electronic applications.

Microwave Plasma CVD reactors use very similar conditions to hot fil-

ament reactors, and despite being significantly more expensive, are now

among the most widely used techniques for diamond growth. In these