Page 249 - Vogel's TEXTBOOK OF QUANTITATIVE CHEMICAL ANALYSIS

P. 249

EilUlPMENT FOR HPLC 8.3

-

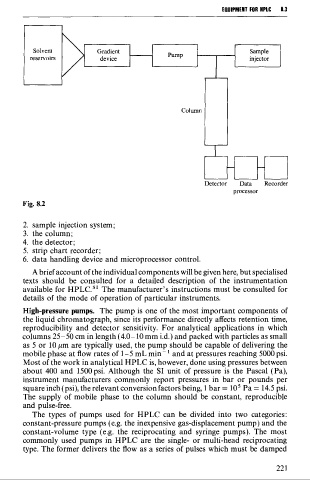

Solvem Gradient Sample

hmp

reservoirs device injector

1 I

Column

- -

Detector Data Recorder

processor

Fig. 8.2

2. sample injection system;

3. the column;

4. the detector;

5. strip chart recorder;

6. data handling device and microprocessor control.

A brief account of the individual components will be given here, but specialised

texts should be consulted for a detailed description of the instrumentation

available for HPLC." The manufacturer's instructions must be consulted for

details of the mode of operation of particular instruments.

High-pressure pumps. The pump is one of the most important components of

the liquid chromatograph, since its performance directly affects retention time,

reproducibility and detector sensitivity. For analytical applications in which

columns 25-50 cm in length (4.0- 10 mm id.) and packed with particles as small

as 5 or 10 pm are typically used, the pump should be capable of delivering the

mobile phase at flow rates of 1-5 mL min-' and at pressures reaching 5000 psi.

Most of the work in analytical HPLC is, however, done using pressures between

about 400 and 1500psi. Although the SI unit of pressure is the Pascal (Pa),

instrument manufacturers commonly report pressures in bar or pounds per

square inch (psi), the relevant conversion factors being, 1 bar = IO5 Pa = 14.5 psi.

The supply of mobile phase to the column should be constant, reproducible

and pulse-free.

The types of pumps used for HPLC can be divided into two categories:

constant-pressure pumps (e.g. the inexpensive gas-displacement pump) and the

constant-volume type (e.g. the reciprocating and syringe pumps). The most

commonly used pumps in HPLC are the single- or multi-head reciprocating

type. The former delivers the flow as a series of pulses which must be damped