Page 220 - Materials Chemistry, Second Edition

P. 220

CAT3525_C07.qxd 1/29/2005 9:57 AM Page 191

Municipal Solid Waste Processing; Materials Recovery Facilities 191

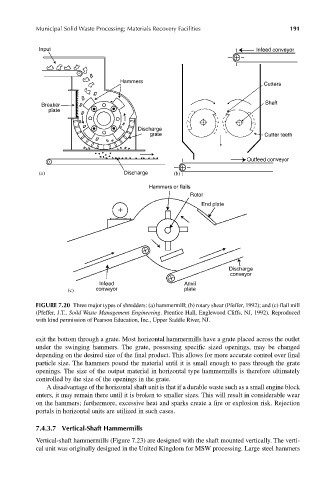

FIGURE 7.20 Three major types of shredders: (a) hammermill; (b) rotary shear (Pfeffer, 1992); and (c) flail mill

(Pfeffer, J.T., Soild Waste Management Engineering. Prentice Hall, Englewood Cliffs, NJ, 1992). Reproduced

with kind permission of Pearson Education, Inc., Upper Saddle River, NJ.

exit the bottom through a grate. Most horizontal hammermills have a grate placed across the outlet

under the swinging hammers. The grate, possessing specific sized openings, may be changed

depending on the desired size of the final product. This allows for more accurate control over final

particle size. The hammers pound the material until it is small enough to pass through the grate

openings. The size of the output material in horizontal type hammermills is therefore ultimately

controlled by the size of the openings in the grate.

A disadvantage of the horizontal shaft unit is that if a durable waste such as a small engine block

enters, it may remain there until it is broken to smaller sizes. This will result in considerable wear

on the hammers; furthermore, excessive heat and sparks create a fire or explosion risk. Rejection

portals in horizontal units are utilized in such cases.

7.4.3.7 Vertical-Shaft Hammermills

Vertical-shaft hammermills (Figure 7.23) are designed with the shaft mounted vertically. The verti-

cal unit was originally designed in the United Kingdom for MSW processing. Large steel hammers