Page 222 - Materials Chemistry, Second Edition

P. 222

CAT3525_C07.qxd 1/29/2005 9:57 AM Page 193

Municipal Solid Waste Processing; Materials Recovery Facilities 193

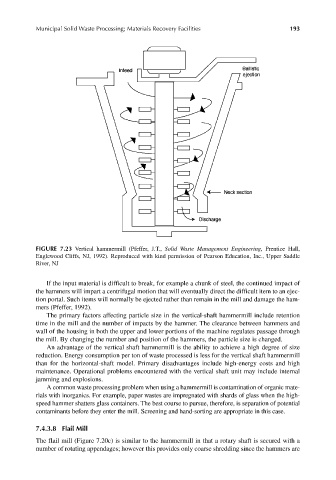

FIGURE 7.23 Vertical hammermill (Pfeffer, J.T., Solid Waste Management Engineering, Prentice Hall,

Englewood Cliffs, NJ, 1992). Reproduced with kind permission of Pearson Education, Inc., Upper Saddle

River, NJ

If the input material is difficult to break, for example a chunk of steel, the continued impact of

the hammers will impart a centrifugal motion that will eventually direct the difficult item to an ejec-

tion portal. Such items will normally be ejected rather than remain in the mill and damage the ham-

mers (Pfeffer, 1992).

The primary factors affecting particle size in the vertical-shaft hammermill include retention

time in the mill and the number of impacts by the hammer. The clearance between hammers and

wall of the housing in both the upper and lower portions of the machine regulates passage through

the mill. By changing the number and position of the hammers, the particle size is changed.

An advantage of the vertical shaft hammermill is the ability to achieve a high degree of size

reduction. Energy consumption per ton of waste processed is less for the vertical shaft hammermill

than for the horizontal-shaft model. Primary disadvantages include high-energy costs and high

maintenance. Operational problems encountered with the vertical shaft unit may include internal

jamming and explosions.

A common waste processing problem when using a hammermill is contamination of organic mate-

rials with inorganics. For example, paper wastes are impregnated with shards of glass when the high-

speed hammer shatters glass containers. The best course to pursue, therefore, is separation of potential

contaminants before they enter the mill. Screening and hand-sorting are appropriate in this case.

7.4.3.8 Flail Mill

The flail mill (Figure 7.20c) is similar to the hammermill in that a rotary shaft is secured with a

number of rotating appendages; however this provides only coarse shredding since the hammers are