Page 226 - Materials Chemistry, Second Edition

P. 226

CAT3525_C07.qxd 1/29/2005 9:57 AM Page 197

Municipal Solid Waste Processing; Materials Recovery Facilities 197

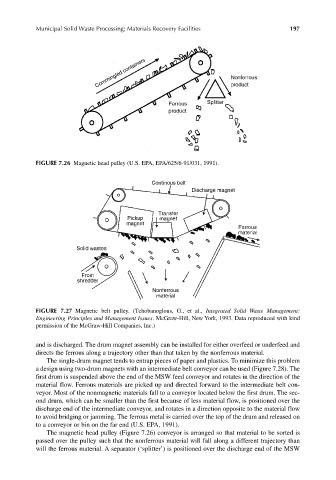

FIGURE 7.26 Magnetic head pulley (U.S. EPA, EPA/625/6-91/031, 1991).

FIGURE 7.27 Magnetic belt pulley. (Tchobanoglous, G., et al., Integrated Solid Waste Management:

Engineering Principles and Management Issues. McGraw-Hill, New York, 1993. Data reproduced with kind

permission of the McGraw-Hill Companies, Inc.)

and is discharged. The drum magnet assembly can be installed for either overfeed or underfeed and

directs the ferrous along a trajectory other than that taken by the nonferrous material.

The single-drum magnet tends to entrap pieces of paper and plastics. To minimize this problem

a design using two-drum magnets with an intermediate belt conveyor can be used (Figure 7.28). The

first drum is suspended above the end of the MSW feed conveyor and rotates in the direction of the

material flow. Ferrous materials are picked up and directed forward to the intermediate belt con-

veyor. Most of the nonmagnetic materials fall to a conveyor located below the first drum. The sec-

ond drum, which can be smaller than the first because of less material flow, is positioned over the

discharge end of the intermediate conveyor, and rotates in a direction opposite to the material flow

to avoid bridging or jamming. The ferrous metal is carried over the top of the drum and released on

to a conveyor or bin on the far end (U.S. EPA, 1991).

The magnetic head pulley (Figure 7.26) conveyor is arranged so that material to be sorted is

passed over the pulley such that the nonferrous material will fall along a different trajectory than

will the ferrous material. A separator (‘splitter’) is positioned over the discharge end of the MSW