Page 227 - Materials Chemistry, Second Edition

P. 227

CAT3525_C07.qxd 1/29/2005 9:57 AM Page 198

198 Waste Management Practices: Municipal, Hazardous, and Industrial

Magnet

Comingled containers

Magnet

Ferrous

product

Cleaned

ferrous

Deflector product

Connecting belt

conveyor

Small nonferrous

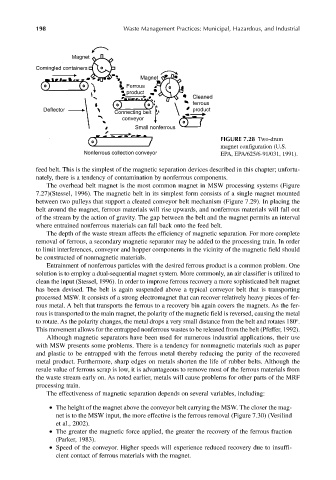

FIGURE 7.28 Two-drum

magnet configuration (U.S.

Nonferrous collection conveyor EPA, EPA/625/6-91/031, 1991).

feed belt. This is the simplest of the magnetic separation devices described in this chapter; unfortu-

nately, there is a tendency of contamination by nonferrous components.

The overhead belt magnet is the most common magnet in MSW processing systems (Figure

7.27)(Stessel, 1996). The magnetic belt in its simplest form consists of a single magnet mounted

between two pulleys that support a cleated conveyor belt mechanism (Figure 7.29). In placing the

belt around the magnet, ferrous materials will rise upwards, and nonferrous materials will fall out

of the stream by the action of gravity. The gap between the belt and the magnet permits an interval

where entrained nonferrous materials can fall back onto the feed belt.

The depth of the waste stream affects the efficiency of magnetic separation. For more complete

removal of ferrous, a secondary magnetic separator may be added to the processing train. In order

to limit interferences, conveyor and hopper components in the vicinity of the magnetic field should

be constructed of nonmagnetic materials.

Entrainment of nonferrous particles with the desired ferrous product is a common problem. One

solution is to employ a dual-sequential magnet system. More commonly, an air classifier is utilized to

clean the input (Stessel, 1996). In order to improve ferrous recovery a more sophisticated belt magnet

has been devised. The belt is again suspended above a typical conveyor belt that is transporting

processed MSW. It consists of a strong electromagnet that can recover relatively heavy pieces of fer-

rous metal. A belt that transports the ferrous to a recovery bin again covers the magnets. As the fer-

rous is transported to the main magnet, the polarity of the magnetic field is reversed, causing the metal

o

to rotate. As the polarity changes, the metal drops a very small distance from the belt and rotates 180 .

This movement allows for the entrapped nonferrous wastes to be released from the belt (Pfeffer, 1992).

Although magnetic separators have been used for numerous industrial applications, their use

with MSW presents some problems. There is a tendency for nonmagnetic materials such as paper

and plastic to be entrapped with the ferrous metal thereby reducing the purity of the recovered

metal product. Furthermore, sharp edges on metals shorten the life of rubber belts. Although the

resale value of ferrous scrap is low, it is advantageous to remove most of the ferrous materials from

the waste stream early on. As noted earlier, metals will cause problems for other parts of the MRF

processing train.

The effectiveness of magnetic separation depends on several variables, including:

• The height of the magnet above the conveyor belt carrying the MSW. The closer the mag-

net is to the MSW input, the more effective is the ferrous removal (Figure 7.30) (Vesilind

et al., 2002).

• The greater the magnetic force applied, the greater the recovery of the ferrous fraction

(Parker, 1983).

• Speed of the conveyor. Higher speeds will experience reduced recovery due to insuffi-

cient contact of ferrous materials with the magnet.