Page 283 - Materials Chemistry, Second Edition

P. 283

CAT3525_C09.qxd 2/8/2005 10:11 AM Page 254

254 Waste Management Practices: Municipal, Hazardous, and Industrial

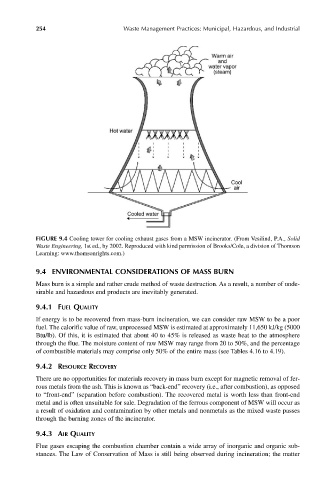

FIGURE 9.4 Cooling tower for cooling exhaust gases from a MSW incinerator. (From Vesilind, P.A., Solid

Waste Engineering, 1st ed., by 2002. Reproduced with kind permission of Brooks/Cole, a division of Thomson

Learning: www.thomsonrights.com.)

9.4 ENVIRONMENTAL CONSIDERATIONS OF MASS BURN

Mass burn is a simple and rather crude method of waste destruction. As a result, a number of unde-

sirable and hazardous end products are inevitably generated.

9.4.1 FUEL QUALITY

If energy is to be recovered from mass-burn incineration, we can consider raw MSW to be a poor

fuel. The calorific value of raw, unprocessed MSW is estimated at approximately 11,650 kJ/kg (5000

Btu/lb). Of this, it is estimated that about 40 to 45% is released as waste heat to the atmosphere

through the flue. The moisture content of raw MSW may range from 20 to 50%, and the percentage

of combustible materials may comprise only 50% of the entire mass (see Tables 4.16 to 4.19).

9.4.2 RESOURCE RECOVERY

There are no opportunities for materials recovery in mass burn except for magnetic removal of fer-

rous metals from the ash. This is known as “back-end” recovery (i.e., after combustion), as opposed

to “front-end” (separation before combustion). The recovered metal is worth less than front-end

metal and is often unsuitable for sale. Degradation of the ferrous component of MSW will occur as

a result of oxidation and contamination by other metals and nonmetals as the mixed waste passes

through the burning zones of the incinerator.

9.4.3 AIR QUALITY

Flue gases escaping the combustion chamber contain a wide array of inorganic and organic sub-

stances. The Law of Conservation of Mass is still being observed during incineration; the matter