Page 524 - Materials Chemistry, Second Edition

P. 524

CAT3525_C15.qxd 1/27/2005 12:40 PM Page 495

Incineration of Hazardous Wastes 495

combustion chamber. The heat from the combustion gas flowing on the outside of the firebox is

transferred to the water within the boiler or waterwall tubes.

Wastes designated as hazardous may be combusted in industrial boilers provided that the wastes

are hazardous solely based on the characteristic of ignitability. Wastes combusted in this manner

usually occur as liquids that are generated on-site. Examples include aliphatic and aromatic sol-

vents, alcohols, and other highly volatile hydrocarbons. The U.S. EPA has required field tests of

operating facilities in destroying hazardous wastes in standard boilers. The tested boilers achieved

performance ratings close to 99.99% DRE.

During day-to-day operations the interior of a boiler becomes dirty due to the accumulation of

particulate matter on the surface of the boiler or waterwall tubes. Such coatings result in reduced

heat transfer. To address the accumulation of particles, a boiler periodically blows high-velocity air

or steam into the unit to scour surfaces. This process is known as soot blowing and is an important

consideration when designing a trial burn. During soot blowing, a combination of previously

deposited metals, soot, and particulate matter is released. This pulse of particulates enters the air

pollution control system. Because of such particulate surges, part of the trial burn must be con-

ducted under soot blowing conditions (U.S. EPA, 1992).

The advantage of the disposal of hazardous wastes in a boiler is a reduction in cost to the waste

generator compared with on- or off-site incineration. The facility obtains a fuel value from the waste,

and cost savings are accrued from not having to dispose of the waste in an RCRA regulated process.

Also, the waste does not have to be transported to a disposal facility. One disadvantage of hazardous

waste incineration in boilers is that the process is not closely regulated and may be subject to acci-

dents or misuse.

15.6.8 CEMENT KILNS

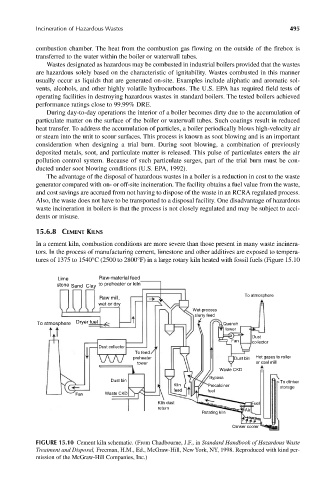

In a cement kiln, combustion conditions are more severe than those present in many waste incinera-

tors. In the process of manufacturing cement, limestone and other additives are exposed to tempera-

tures of 1375 to 1540°C (2500 to 2800°F) in a large rotary kiln heated with fossil fuels (Figure 15.10

Lime Raw-material feed

to preheater or kiln

stone Sand Clay

To atmosphere

Raw mill,

wet or dry

Wet-process

slurry feed

To atmosphere Dryer fuel Quench

tower

Dust

Fan collector

Dust collector

To feed

preheater Dust bin Hot gases to roller

tower or coal mill

Waste CKD

Bypass

Dust bin To clinker

Kiln Precalciner storage

feed fuel

Fan Waste CKD

Kiln dust Fuel

return Air

Rotating kiln

Clinker cooler

FIGURE 15.10 Cement kiln schematic. (From Chadbourne, J.F., in Standard Handbook of Hazardous Waste

Treatment and Disposal, Freeman, H.M., Ed., McGraw-Hill, New York, NY, 1998. Reproduced with kind per-

mission of the McGraw-Hill Companies, Inc.)