Page 215 - Wastewater Solids Incineration Systems

P. 215

Ash Handling and Recycling 181

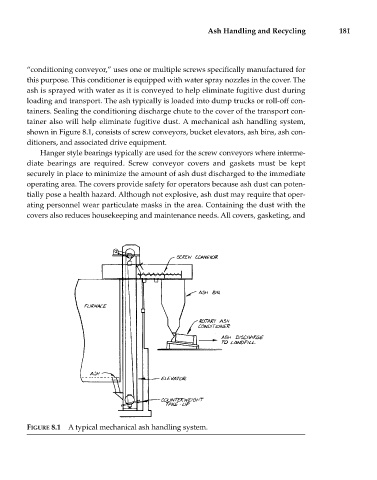

“conditioning conveyor,” uses one or multiple screws specifically manufactured for

this purpose. This conditioner is equipped with water spray nozzles in the cover. The

ash is sprayed with water as it is conveyed to help eliminate fugitive dust during

loading and transport. The ash typically is loaded into dump trucks or roll-off con-

tainers. Sealing the conditioning discharge chute to the cover of the transport con-

tainer also will help eliminate fugitive dust. A mechanical ash handling system,

shown in Figure 8.1, consists of screw conveyors, bucket elevators, ash bins, ash con-

ditioners, and associated drive equipment.

Hanger style bearings typically are used for the screw conveyors where interme-

diate bearings are required. Screw conveyor covers and gaskets must be kept

securely in place to minimize the amount of ash dust discharged to the immediate

operating area. The covers provide safety for operators because ash dust can poten-

tially pose a health hazard. Although not explosive, ash dust may require that oper-

ating personnel wear particulate masks in the area. Containing the dust with the

covers also reduces housekeeping and maintenance needs. All covers, gasketing, and

FIGURE 8.1 A typical mechanical ash handling system.