Page 219 - Wastewater Solids Incineration Systems

P. 219

Ash Handling and Recycling 185

FILTER SILENCER

P

FILTER BAGS

VACUUM PUMP

L P

INCINERATOR WASTE HEAT BOILER ASH

(TYPICAL) FILTER RECEIVER

L L

DIVERTER VALVE

* *

L L

ASH

CLINKER BIN

BREAKER ASH

COOLER

X X

T T

* ROTARY AIR LOCK *

AIR INLET

TRUCK LOADING

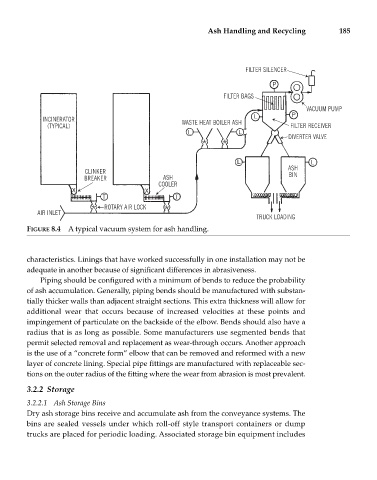

FIGURE 8.4 A typical vacuum system for ash handling.

characteristics. Linings that have worked successfully in one installation may not be

adequate in another because of significant differences in abrasiveness.

Piping should be configured with a minimum of bends to reduce the probability

of ash accumulation. Generally, piping bends should be manufactured with substan-

tially thicker walls than adjacent straight sections. This extra thickness will allow for

additional wear that occurs because of increased velocities at these points and

impingement of particulate on the backside of the elbow. Bends should also have a

radius that is as long as possible. Some manufacturers use segmented bends that

permit selected removal and replacement as wear-through occurs. Another approach

is the use of a “concrete form” elbow that can be removed and reformed with a new

layer of concrete lining. Special pipe fittings are manufactured with replaceable sec-

tions on the outer radius of the fitting where the wear from abrasion is most prevalent.

3.2.2 Storage

3.2.2.1 Ash Storage Bins

Dry ash storage bins receive and accumulate ash from the conveyance systems. The

bins are sealed vessels under which roll-off style transport containers or dump

trucks are placed for periodic loading. Associated storage bin equipment includes