Page 348 - Wastewater Solids Incineration Systems

P. 348

Appendix C Determination of Wastewater Solids Incineration Related Costs 309

3.0 STANDARD MULTIPLE-HEARTH FURNACE

SYSTEM EXAMPLE

The following is a summary of the costs incurred by the Northeast Ohio Regional

Sewer District (NEORSD) in 2004 to incinerate wastewater solids at its Westerly

WWTP (Dominak, 2005). Westerly has two multiple-hearth furnaces (MHFs) that

were originally constructed in 1978 and underwent a significant renovation in 1994

to 1995. Wastewater solids are injected to hearth number 4, and the top hearths are

used as an afterburning zone to minimize emissions of potentially toxic organic com-

pounds. Table C.1 contains a summary of some of the differences between waste-

water solids and wastewater solids incineration-related costs at the NEORSD’s

Southerly and Westerly WWTPs.

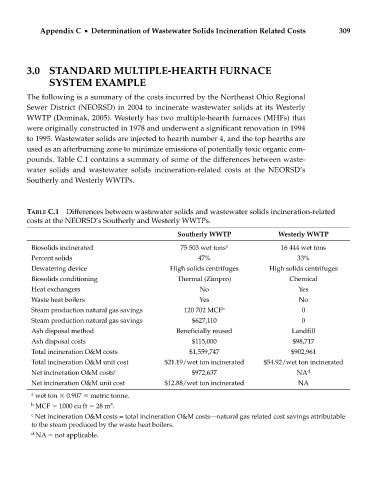

TABLE C.1 Differences between wastewater solids and wastewater solids incineration-related

costs at the NEORSD’s Southerly and Westerly WWTPs.

Southerly WWTP Westerly WWTP

Biosolids incinerated 75 503 wet tons a 16 444 wet tons

Percent solids 47% 33%

Dewatering device High solids centrifuges High solids centrifuges

Biosolids conditioning Thermal (Zimpro) Chemical

Heat exchangers No Yes

Waste heat boilers Yes No

Steam production natural gas savings 120 702 MCF b 0

Steam production natural gas savings $627,110 0

Ash disposal method Beneficially reused Landfill

Ash disposal costs $115,000 $98,717

Total incineration O&M costs $1,559,747 $902,961

Total incineration O&M unit cost $21.19/wet ton incinerated $54.92/wet ton incinerated

Net incineration O&M costs c $972,637 NA d

Net incineration O&M unit cost $12.88/wet ton incinerated NA

a wet ton 0.907 metric tonne.

3

b MCF 1000 cu ft 28 m .

c Net incineration O&M costs = total incineration O&M costs—natural gas related cost savings attributable

to the steam produced by the waste heat boilers.

d NA not applicable.