Page 221 - Water Engineering Hydraulics, Distribution and Treatment

P. 221

Gate N

Gauge B

Gate M

To private

From public

3

/ 4 ˝ test

system

water main

Gauge A

drain D

3

/ 4 ˝ test drain E

Check valve G

Check valve F

Steel foothold inserts

Brick or concrete pit

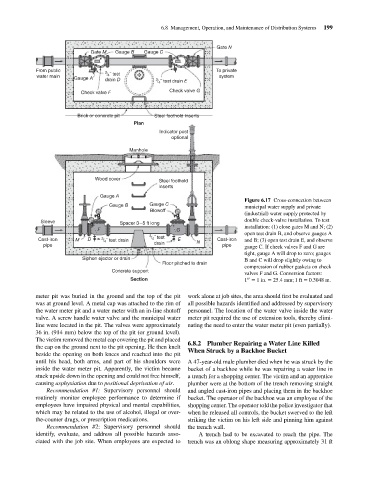

Plan Gauge C 6.8 Management, Operation, and Maintenance of Distribution Systems 199

Indicator post

optional

Manhole

Wood cover

Steel foothold

inserts

Gauge A

Figure 6.17 Cross-connection between

Gauge B Gauge C municipal water supply and private

Blowoff

(industrial) water supply protected by

Sleeve Spacer 3–5 ft long double check-valve installation. To test

F G installation: (1) close gates M and N; (2)

open test drain B, and observe gauges A

3 / 4 ˝ test

Cast-iron M D 3 / 4 ˝ test drain E N Cast-iron and B; (3) open test drain E, and observe

pipe drain pipe gauge C. If check valves F and G are

tight, gauge A will drop to zero; gauges

Siphon ejector or drain B and C will drop slightly owing to

Floor pitched to drain

compression of rubber gaskets on check

Concrete support

valves F and G. Conversion factors:

Section 1 = 1in. = 25.4 mm; 1 ft = 0.3048 m.

′′

meter pit was buried in the ground and the top of the pit work alone at job sites, the area should first be evaluated and

was at ground level. A metal cap was attached to the rim of all possible hazards identified and addressed by supervisory

the water meter pit and a water meter with an in-line shutoff personnel. The location of the water valve inside the water

valve. A screw handle water valve and the municipal water meter pit required the use of extension tools, thereby elimi-

line were located in the pit. The valves were approximately nating the need to enter the water meter pit (even partially).

36 in. (914 mm) below the top of the pit (or ground level).

The victim removed the metal cap covering the pit and placed

6.8.2 Plumber Repairing a Water Line Killed

the cap on the ground next to the pit opening. He then knelt

When Struck by a Backhoe Bucket

beside the opening on both knees and reached into the pit

until his head, both arms, and part of his shoulders were A 47-year-old male plumber died when he was struck by the

inside the water meter pit. Apparently, the victim became bucket of a backhoe while he was repairing a water line in

stuck upside down in the opening and could not free himself, a trench for a shopping center. The victim and an apprentice

causing asphyxiation due to positional deprivation of air. plumber were at the bottom of the trench removing straight

Recommendation #1: Supervisory personnel should and angled cast-iron pipes and placing them in the backhoe

routinely monitor employee performance to determine if bucket. The operator of the backhoe was an employee of the

employees have impaired physical and mental capabilities, shopping center. The operator told the police investigator that

which may be related to the use of alcohol, illegal or over- when he released all controls, the bucket swerved to the left

the-counter drugs, or prescription medications. striking the victim on his left side and pinning him against

Recommendation #2: Supervisory personnel should the trench wall.

identify, evaluate, and address all possible hazards asso- A trench had to be excavated to reach the pipe. The

ciated with the job site. When employees are expected to trench was an oblong shape measuring approximately 31 ft