Page 220 - Water Engineering Hydraulics, Distribution and Treatment

P. 220

198

Chapter 6

Water Distribution Systems: Components, Design, and Operation

Roof tank (tank may be at

any other level as well)

Float-controlled valve

Overflow

Frost boxes

To sprinkler system or

Check valve closes when

process-water system

pumps are in operation

Check valve

From private supply

Surface water

From municipal supply

To building Fire pumps or

distribution system process-water pumps

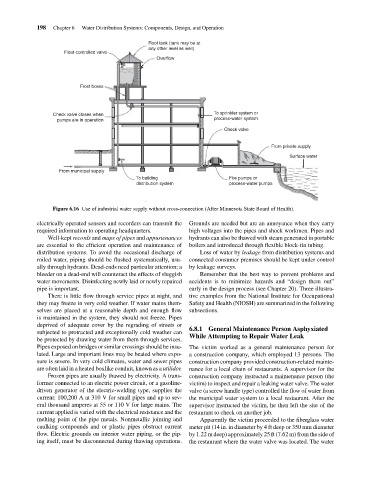

Figure 6.16 Use of industrial water supply without cross-connection (After Minnesota State Board of Health).

electrically operated sensors and recorders can transmit the Grounds are needed but are an annoyance when they carry

required information to operating headquarters. high voltages into the pipes and shock workmen. Pipes and

Well-kept records and maps of pipes and appurtenances hydrants can also be thawed with steam generated in portable

are essential to the efficient operation and maintenance of boilers and introduced through flexible block-tin tubing.

distribution systems. To avoid the occasional discharge of Loss of water by leakage from distribution systems and

roiled water, piping should be flushed systematically, usu- connected consumer premises should be kept under control

ally through hydrants. Dead-ends need particular attention; a by leakage surveys.

bleeder on a dead-end will counteract the effects of sluggish Remember that the best way to prevent problems and

water movements. Disinfecting newly laid or newly repaired accidents is to minimize hazards and “design them out”

pipe is important. early in the design process (see Chapter 20). Three illustra-

There is little flow through service pipes at night, and tive examples from the National Institute for Occupational

they may freeze in very cold weather. If water mains them- Safety and Health (NIOSH) are summarized in the following

selves are placed at a reasonable depth and enough flow subsections.

is maintained in the system, they should not freeze. Pipes

deprived of adequate cover by the regrading of streets or 6.8.1 General Maintenance Person Asphyxiated

subjected to protracted and exceptionally cold weather can

While Attempting to Repair Water Leak

be protected by drawing water from them through services.

Pipes exposed on bridges or similar crossings should be insu- The victim worked as a general maintenance person for

lated. Large and important lines may be heated where expo- a construction company, which employed 13 persons. The

sure is severe. In very cold climates, water and sewer pipes construction company provided construction-related mainte-

are often laid in a heated boxlike conduit, known as a utilidor. nance for a local chain of restaurants. A supervisor for the

Frozen pipes are usually thawed by electricity. A trans- construction company instructed a maintenance person (the

former connected to an electric power circuit, or a gasoline- victim) to inspect and repair a leaking water valve. The water

driven generator of the electric-welding type, supplies the valve (a screw handle type) controlled the flow of water from

current: 100,200 A at 310 V for small pipes and up to sev- the municipal water system to a local restaurant. After the

eral thousand amperes at 55 or 110 V for large mains. The supervisor instructed the victim, he then left the site of the

current applied is varied with the electrical resistance and the restaurant to check on another job.

melting point of the pipe metals. Nonmetallic jointing and Apparently the victim proceeded to the fiberglass water

caulking compounds and or plastic pipes obstruct current meter pit (14 in. in diameter by 4 ft deep or 350 mm diameter

flow. Electric grounds on interior water piping, or the pip- by 1.22 m deep) approximately 25 ft (7.62 m) from the side of

ing itself, must be disconnected during thawing operations. the restaurant where the water valve was located. The water