Page 97 - Water Engineering Hydraulics, Distribution and Treatment

P. 97

75

3.17 Well Construction

3.17.1 Dug Wells

deeper and deeper, sections of rod are added to the auger

stem. Bits up to 36 in. (914 mm) in diameter have been used

Small dug wells are generally excavated by hand. In loose

successfully, and wells have been enlarged in diameter up

overburden, they are cribbed with timber; lined with brick,

to 48 in. (1219 mm) by reaming. A concrete, tile, or metal

rubble, or concrete; or cased with large-diameter vitrified tile

casing is inserted in the hole and cemented in place before

or concrete pipe. In rock, they are commonly left unlined.

the strainer is installed.

Excavation is continued until water flows in more rapidly

than it can be bailed out. Dug wells should be completed

when the water table is at or near its lowest level. Otherwise,

3.17.4 Drilled Wells

they may have to be deepened at a later date.

High-capacity, deep wells are constructed by drilling.

Large and deep dug wells are often constructed by sink-

Because the water-bearing materials vary so widely, no one

ing their liners as excavation proceeds. The lead ring has a

method of drilling can be adopted under all conditions. The

steel cutting edge; new rings are added as excavation pro-

method of drilling is selected to suit the particular condi-

gresses.

tions of a site. The systems of drilling used in water-well

construction are based on either the percussion or the rotary

3.17.2 Driven and Jetted Wells principle.

Wells can be driven into relatively shallow sand formations.

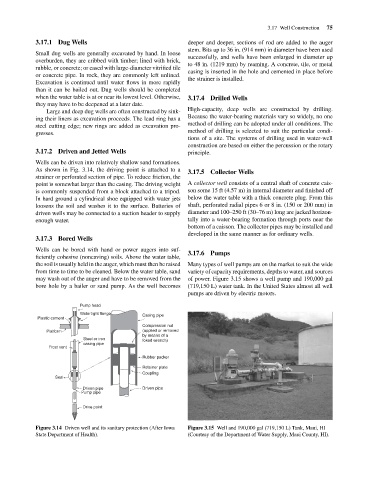

As shown in Fig. 3.14, the driving point is attached to a 3.17.5 Collector Wells

strainer or perforated section of pipe. To reduce friction, the

point is somewhat larger than the casing. The driving weight A collector well consists of a central shaft of concrete cais-

is commonly suspended from a block attached to a tripod. son some 15 ft (4.57 m) in internal diameter and finished off

In hard ground a cylindrical shoe equipped with water jets below the water table with a thick concrete plug. From this

loosens the soil and washes it to the surface. Batteries of shaft, perforated radial pipes 6 or 8 in. (150 or 200 mm) in

driven wells may be connected to a suction header to supply diameter and 100–250 ft (30–76 m) long are jacked horizon-

enough water. tally into a water-bearing formation through ports near the

bottom of a caisson. The collector pipes may be installed and

developed in the same manner as for ordinary wells.

3.17.3 Bored Wells

Wells can be bored with hand or power augers into suf- 3.17.6 Pumps

ficiently cohesive (noncaving) soils. Above the water table,

the soil is usually held in the auger, which must then be raised Many types of well pumps are on the market to suit the wide

from time to time to be cleaned. Below the water table, sand variety of capacity requirements, depths to water, and sources

may wash out of the auger and have to be removed from the of power. Figure 3.15 shows a well pump and 190,000 gal

bore hole by a bailer or sand pump. As the well becomes (719,150 L) water tank. In the United States almost all well

pumps are driven by electric motors.

Pump head

Watertight flange Casing pipe

Plastic cement

Compression nut

Platform (applied or removed

by means of a

Steel or iron foked wrench)

casing pipe

Frost vent

Rubber packer

Retainer plate

Coupling

Seal

Driven pipe Driven pipe

Pump pipe

Drive point

Figure 3.14 Driven well and its sanitary protection (After Iowa Figure 3.15 Well and 190,000 gal (719,150 L) Tank, Maui, HI

State Department of Health). (Courtesy of the Department of Water Supply, Maui County, HI).