Page 225 - Water Loss Control

P. 225

198 Cha pte r T w e l v e

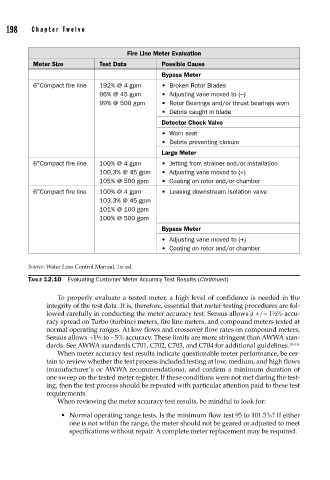

Fire Line Meter Evaluation

Meter Size Test Data Possible Cause

Bypass Meter

6"Compact fire line 192% @ 4 gpm • Broken Rotor Blades

96% @ 45 gpm • Adjusting vane moved to (−)

99% @ 500 gpm • Rotor Bearings and/or thrust bearings worn

• Debris caught in blade

Detector Check Valve

• Worn seat

• Debris preventing closure

Large Meter

6"Compact fire line 100% @ 4 gpm • Jetting from strainer and/or installation

100.3% @ 45 gpm • Adjusting vane moved to (+)

105% @ 500 gpm • Coating on rotor and/or chamber

6"Compact fire line 100% @ 4 gpm • Leaking downstream isolation valve

103.3% @ 45 gpm

101% @ 100 gpm

100% @ 500 gpm

Bypass Meter

• Adjusting vane moved to (+)

• Coating on rotor and/or chamber

Source: Water Loss Control Manual, 1st ed.

TABLE 12.10 Evaluating Customer Meter Accuracy Test Results (Continued)

To properly evaluate a tested meter, a high level of confidence is needed in the

integrity of the test data. It is, therefore, essential that meter testing procedures are fol-

lowed carefully in conducting the meter accuracy test. Sensus allows a +/− 1½% accu-

racy spread on Turbo (turbine) meters, fire line meters, and compound meters tested at

normal operating ranges. At low flows and crossover flow rates on compound meters,

Sensus allows +1½ to −5% accuracy. These limits are more stringent than AWWA stan-

dards. See AWWA standards C701, C702, C703, and C704 for additional guidelines. 11–14

When meter accuracy test results indicate questionable meter performance, be cer-

tain to review whether the test process included testing at low, medium, and high flows

(manufacturer’s or AWWA recommendations), and confirm a minimum duration of

one sweep on the tested meter register. If these conditions were not met during the test-

ing, then the test process should be repeated with particular attention paid to these test

requirements.

When reviewing the meter accuracy test results, be mindful to look for:

• Normal operating range tests. Is the minimum flow test 95 to 101.5%? If either

one is not within the range, the meter should not be geared or adjusted to meet

specifications without repair. A complete meter replacement may be required.