Page 303 - Water Loss Control

P. 303

272 Cha pte r S i x tee n

Correlator

Leak

l l Td ∗ v

D

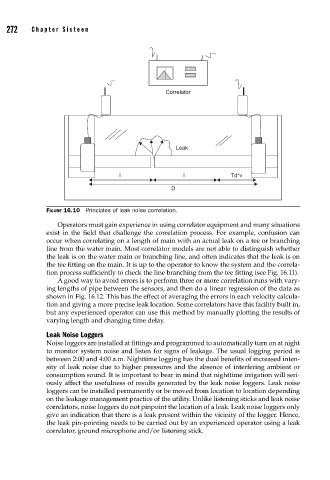

FIGURE 16.10 Principles of leak noise correlation.

Operators must gain experience in using correlator equipment and many situations

exist in the field that challenge the correlation process. For example, confusion can

occur when correlating on a length of main with an actual leak on a tee or branching

line from the water main. Most correlator models are not able to distinguish whether

the leak is on the water main or branching line, and often indicates that the leak is on

the tee fitting on the main. It is up to the operator to know the system and the correla-

tion process sufficiently to check the line branching from the tee fitting (see Fig. 16.11).

A good way to avoid errors is to perform three or more correlation runs with vary-

ing lengths of pipe between the sensors, and then do a linear regression of the data as

shown in Fig. 16.12. This has the effect of averaging the errors in each velocity calcula-

tion and giving a more precise leak location. Some correlators have this facility built in,

but any experienced operator can use this method by manually plotting the results of

varying length and changing time delay.

Leak Noise Loggers

Noise loggers are installed at fittings and programmed to automatically turn on at night

to monitor system noise and listen for signs of leakage. The usual logging period is

between 2:00 and 4:00 a.m. Nighttime logging has the dual benefits of increased inten-

sity of leak noise due to higher pressures and the absence of interfering ambient or

consumption sound. It is important to bear in mind that nighttime irrigation will seri-

ously affect the usefulness of results generated by the leak noise loggers. Leak noise

loggers can be installed permanently or be moved from location to location depending

on the leakage management practice of the utility. Unlike listening sticks and leak noise

correlators, noise loggers do not pinpoint the location of a leak. Leak noise loggers only

give an indication that there is a leak present within the vicinity of the logger. Hence,

the leak pin-pointing needs to be carried out by an experienced operator using a leak

correlator, ground microphone and/or listening stick.