Page 308 - Water Loss Control

P. 308

Contr olling Real Losses in the Field—Pr oactive Leak Detection 277

Q

Flow drops to stable

minimum around 3:00 a.m.

50

40 Shut one

Shut two

30

20 Shut three

10

0

3:00 3:15 3:30 3:45

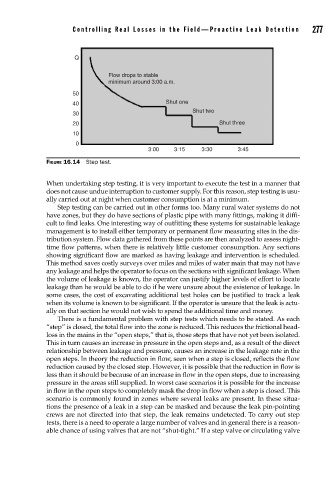

FIGURE 16.14 Step test.

When undertaking step testing, it is very important to execute the test in a manner that

does not cause undue interruption to customer supply. For this reason, step testing is usu-

ally carried out at night when customer consumption is at a minimum.

Step testing can be carried out in other forms too. Many rural water systems do not

have zones, but they do have sections of plastic pipe with many fittings, making it diffi-

cult to find leaks. One interesting way of outfitting these systems for sustainable leakage

management is to install either temporary or permanent flow measuring sites in the dis-

tribution system. Flow data gathered from these points are then analyzed to assess night-

time flow patterns, when there is relatively little customer consumption. Any sections

showing significant flow are marked as having leakage and intervention is scheduled.

This method saves costly surveys over miles and miles of water main that may not have

any leakage and helps the operator to focus on the sections with significant leakage. When

the volume of leakage is known, the operator can justify higher levels of effort to locate

leakage than he would be able to do if he were unsure about the existence of leakage. In

some cases, the cost of excavating additional test holes can be justified to track a leak

when its volume is known to be significant. If the operator is unsure that the leak is actu-

ally on that section he would not wish to spend the additional time and money.

There is a fundamental problem with step tests which needs to be stated. As each

“step” is closed, the total flow into the zone is reduced. This reduces the frictional head-

loss in the mains in the “open steps,” that is, those steps that have not yet been isolated.

This in turn causes an increase in pressure in the open steps and, as a result of the direct

relationship between leakage and pressure, causes an increase in the leakage rate in the

open steps. In theory the reduction in flow, seen when a step is closed, reflects the flow

reduction caused by the closed step. However, it is possible that the reduction in flow is

less than it should be because of an increase in flow in the open steps, due to increasing

pressure in the areas still supplied. In worst case scenarios it is possible for the increase

in flow in the open steps to completely mask the drop in flow when a step is closed. This

scenario is commonly found in zones where several leaks are present. In these situa-

tions the presence of a leak in a step can be masked and because the leak pin-pointing

crews are not directed into that step, the leak remains undetected. To carry out step

tests, there is a need to operate a large number of valves and in general there is a reason-

able chance of using valves that are not “shut-tight.” If a step valve or circulating valve