Page 466 - Water and wastewater engineering

P. 466

GRANULAR FILTRATION 11-39

In addition to providing for a minimum depth of water, operational control must be provided to

accommodate the increase in headloss during operation. Three methods are used to accommodate

the increase in headloss during filtration: (1) maintaining a constant head in the filter effluent by the

use of a modulating control valve, (2) maintaining a constant head in the filter effluent and allowing

the water level to rise, and (3) maintaining a constant headloss and allowing the filtration rate to

decline. These are discussed in detail by Castro et al. (2005), Monk (1987), and MWH (2005).

Some Important Appurtenances

Many features of the filter design are beyond the scope of this text, but a few are sufficiently

noteworthy to identify them here.

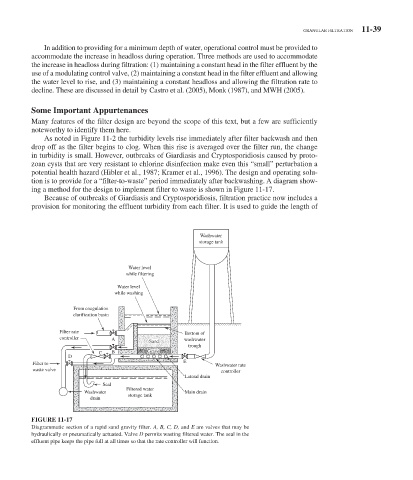

As noted in Figure 11-2 the turbidity levels rise immediately after filter backwash and then

drop off as the filter begins to clog. When this rise is averaged over the filter run, the change

in turbidity is small. However, outbreaks of Giardiasis and Cryptosporidiosis caused by proto-

zoan cysts that are very resistant to chlorine disinfection make even this “small” perturbation a

potential health hazard (Hibler et al., 1987; Kramer et al., 1996). The design and operating solu-

tion is to provide for a “filter-to-waste” period immediately after backwashing. A diagram show-

ing a method for the design to implement filter to waste is shown in Figure 11-17 .

Because of outbreaks of Giardiasis and Cryptosporidiosis, filtration practice now includes a

provision for monitoring the effluent turbidity from each filter. It is used to guide the length of

Washwater

storage tank

Water level

while filtering

Water level

while washing

From coagulation

clarification basin

Filter rate Bottom of

controller A Sand washwater

trough

C B Gravel

D

E

Filter to Washwater rate

waste valve

controller

Lateral drain

Seal

Filtered water

Washwater Main drain

storage tank

drain

FIGURE 11-17

Diagrammatic section of a rapid sand gravity filter. A, B, C, D, and E are valves that may be

hydraulically or pneumatically actuated. Valve D permits wasting filtered water. The seal in the

effluent pipe keeps the pipe full at all times so that the rate controller will function.