Page 128 - Welding Robots Technology, System Issues, and Applications

P. 128

Robotic Welding: System Issues 115

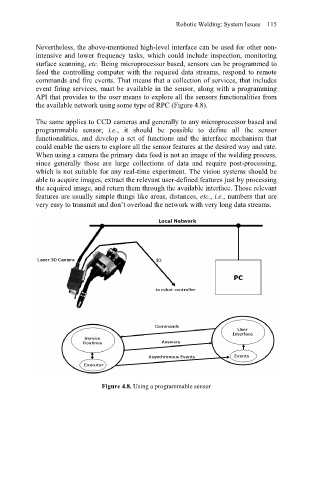

Nevertheless, the above-mentioned high-level interface can be used for other non-

intensive and lower frequency tasks, which could include inspection, monitoring

surface scanning, etc. Being microprocessor based, sensors can be programmed to

feed the controlling computer with the required data streams, respond to remote

commands and fire events. That means that a collection of services, that includes

event firing services, must be available in the sensor, along with a programming

API that provides to the user means to explore all the sensors functionalities from

the available network using some type of RPC (Figure 4.8).

The same applies to CCD cameras and generally to any microprocessor based and

programmable sensor, i.e., it should be possible to define all the sensor

functionalities, and develop a set of functions and the interface mechanism that

could enable the users to explore all the sensor features at the desired way and rate.

When using a camera the primary data feed is not an image of the welding process,

since generally those are large collections of data and require post-processing,

which is not suitable for any real-time experiment. The vision systems should be

able to acquire images, extract the relevant user-defined features just by processing

the acquired image, and return them through the available interface. Those relevant

features are usually simple things like areas, distances, etc., i.e., numbers that are

very easy to transmit and don’t overload the network with very long data streams.

Figure 4.8. Using a programmable sensor