Page 123 - Welding Robots Technology, System Issues, and Applications

P. 123

110 Welding Robots

considered, the most used approach with CCD cameras is to make a teaching pass

before the welding process is actually initiated. Theoretically this is a good

solution since a good reading of the welding seam can be recorded and used to

guide the system during the welding process. The drawbacks of this approach are

the reduction of arc-on time and the insensitivity to deviations, even if small, of the

welding seam that can happen due to the extremely high temperatures

characteristic of the welding process and deficiencies on the material of the plates

to be welded [13]-[19].

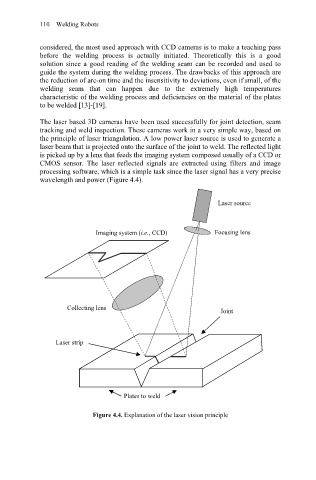

The laser based 3D cameras have been used successfully for joint detection, seam

tracking and weld inspection. These cameras work in a very simple way, based on

the principle of laser triangulation. A low power laser source is used to generate a

laser beam that is projected onto the surface of the joint to weld. The reflected light

is picked up by a lens that feeds the imaging system composed usually of a CCD or

CMOS sensor. The laser reflected signals are extracted using filters and image

processing software, which is a simple task since the laser signal has a very precise

wavelength and power (Figure 4.4).

Laser source

Imaging system (i.e., CCD) Focusing lens

Collecting lens

Joint

Laser strip

Plates to weld

Figure 4.4. Explanation of the laser vision principle