Page 122 - Welding Robots Technology, System Issues, and Applications

P. 122

Robotic Welding: System Issues 109

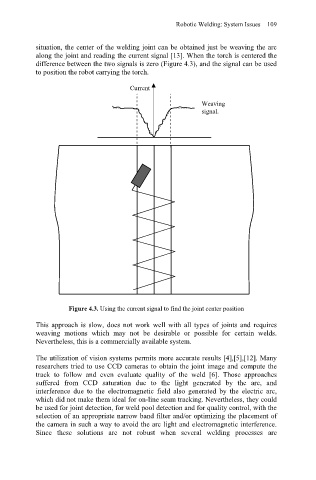

situation, the center of the welding joint can be obtained just be weaving the arc

along the joint and reading the current signal [13]. When the torch is centered the

difference between the two signals is zero (Figure 4.3), and the signal can be used

to position the robot carrying the torch.

Current

Weaving

signal.

Figure 4.3. Using the current signal to find the joint center position

This approach is slow, does not work well with all types of joints and requires

weaving motions which may not be desirable or possible for certain welds.

Nevertheless, this is a commercially available system.

The utilization of vision systems permits more accurate results [4],[5],[12]. Many

researchers tried to use CCD cameras to obtain the joint image and compute the

track to follow and even evaluate quality of the weld [6]. Those approaches

suffered from CCD saturation due to the light generated by the arc, and

interference due to the electromagnetic field also generated by the electric arc,

which did not make them ideal for on-line seam tracking. Nevertheless, they could

be used for joint detection, for weld pool detection and for quality control, with the

selection of an appropriate narrow band filter and/or optimizing the placement of

the camera in such a way to avoid the arc light and electromagnetic interference.

Since these solutions are not robust when several welding processes are